There’s a wide variety of metal fabrication projects that require welded parts. We understand that welding is a crucial aspect of the manufacturing process, but with so many different methods, it can be hard to understand the difference or determine which method is best.

Many people ask, “What’s the difference between MIG and TIG welding?” The two processes do have some aspects in common. Both processes use electrical arcs to produce heat and join metallic objects and both processes incorporate an inert gas mixture to prevent corrosion of welding electrode. Whether you’re unfamiliar or just need a quick review, read on for the differences between MIG welding and TIG welding.

CAMM Metals

Recent Posts

Topics: MIG Welding, TIG Welding, Welding, Certified Welding Inspector

Tips to Obtain An Accurate Metal Fabrication Project Quote

All too often, it can be quite tempting to send your initial parts drawings to a metal fabrication company for a quick estimate to get the ball rolling on your next project. Perhaps you are seeking to gain a general idea on what your project might cost or you are facing a deadline and need to get something for your customer to review.

It’s crucial to recognize that the accuracy of your fabrication project estimate is only as accurate as the drawings you provide. For an accurate estimate, it’s critical that you provide as much information as you can. This blog post will explore why it's important to provide a fabrication company with detailed parts drawings and specifications when seeking a quote for your fabrication project.

Topics: metal fabrication quote, Metal Fabrication Process, Saving Money on Metal Fabrication

Why Do Companies Outsource Metal Fabrication Projects?

Opting to outsource your custom metal fabrication project means that you don’t have to worry about investing in costly equipment or maintaining a workforce who can produce your materials. Outsourcing can dramatically decrease your costs in these areas, however there are many secondary reasons to consider outsourcing with a reputable metal fabricator. This blog post provides an overview of three common reasons why companies typically outsource their metal fabrication projects.

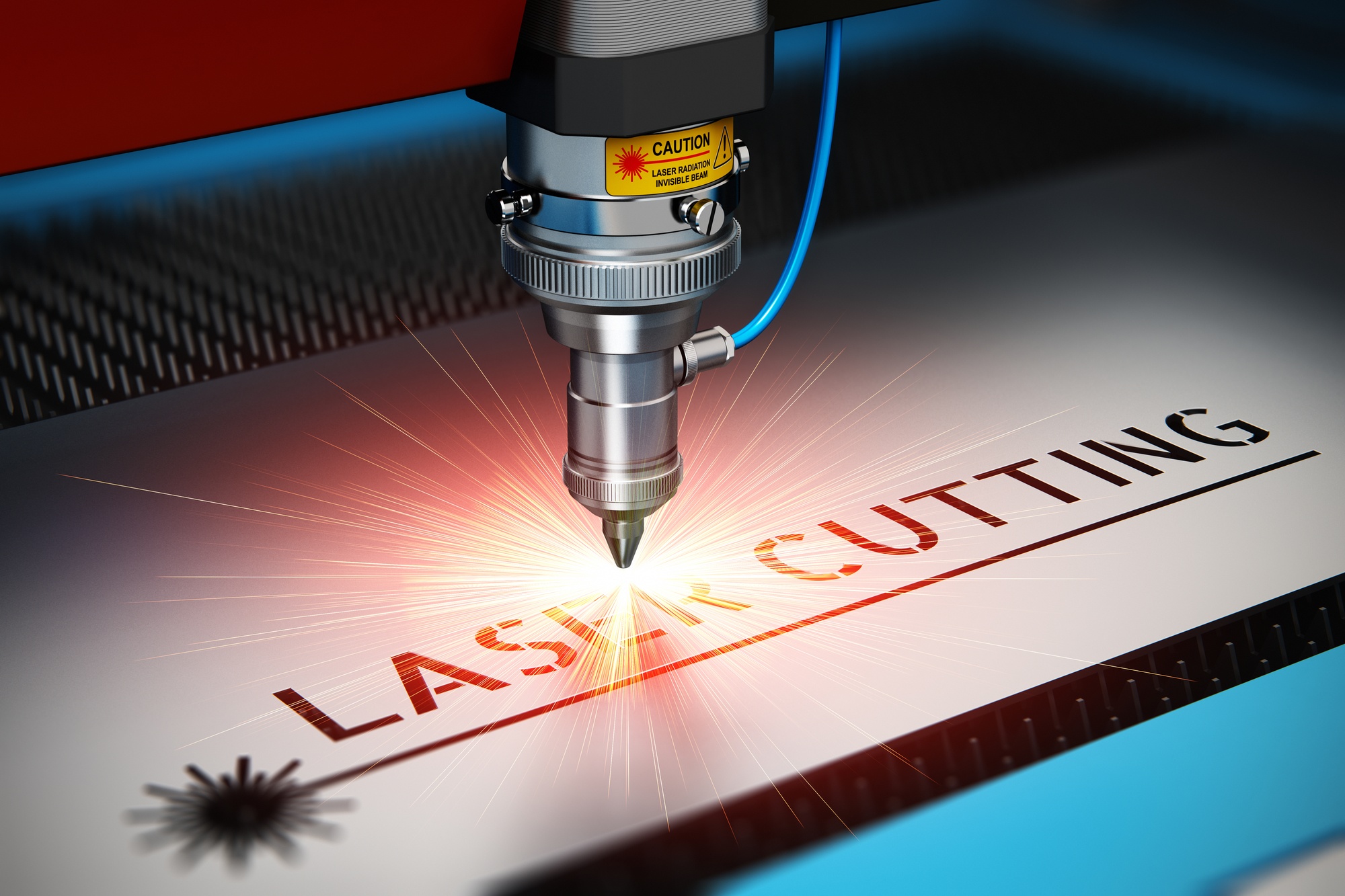

Laser cutting offers clear and tangible advantages over traditional manufacturing processes. Laser cutting’s combination of highly focused energy and pressure allows for operators to cut on a much smaller and narrower area of material, with significantly reduced heat waste and scrap levels. Because of its highly precise and compact area of impact, laser cutting allows for the creation of complex geometrical shapes with smoother edges and cleaner-cut finishes.

For these reasons, laser cutting has become a renowned manufacturing method for automotive, aerospace, and metalworking projects.

Continue reading for a more in-depth examination of the unique benefits associated with laser cutting.

Tips to Keep In Mind When Developing Roll Formed Parts

Most conventional metal fabricators have the ability to accommodate almost any part design requests, as long as you’re willing to cover the associated costs. With a proper roll formed part, there are no additional costs or considerations: increased lead times are nonexistent, scrap is reduced to virtually nothing and your designed part is produced efficiently and with great repeatability.

This blog post aims to help those who are interested in the basics of creating an efficient, cost-effective part.

Choosing the Right Material

Great parts depend on choosing the right materials. While your materials should be high-quality, it’s important that you choose a material that ’s appropriate for the roll forming process and your intended application. So, what types of materials are the best choice for roll forming?

Topics: Roll Forming

4 Features That Make Waterjet Cutting The Right Choice For Your Next Metal Fabrication Project

Over the years, water jet cutting has become an increasingly popular cutting method used for a wide variety of projects. Compared with other cutting methods, waterjet cutting yields cleaner results, more precision and reduced costs without some of the drawbacks associated with other methods, like thermal distortion or rough finished edges.

This blog post will help you to determine if waterjet cutting is the proper choice for your next project. We’ll cover how waterjet cutting works, its best uses, and the primary benefits.

Topics: Waterjet Cutting, Waterjet cutting services, waterjet cutter

Tips for Your Next Metal Enclosure Fabrication Project

Each and every metal enclosure project is started with the seed of an idea to solve a particular problem. For example, consider this situation: you must help design a metal enclosure for an oddly sized and sensitive machine that must stay contained in a hazardous location, which will include moisture and exposure to high temperatures.

After dozens of metal enclosure projects, CAMM Metals has the experience necessary to develop uniquely efficient designs that meet a wide variety of distinct requirements. From the enclosure design and material selection to the chosen process and the quality of the equipment, every step is critical. So if you’re looking for an enclosure to protect your pristine electrical equipment, take a few moments to consider how your preferred company is manufacturing metal enclosures.

Regardless of situation, fabricating metal enclosures requires top-notch quality materials, state-of-the-art equipment and expert technicians. Continue reading this post, as we discuss several tips to help ensure your next metal enclosure fabrication project is a success.

Topics: Custom Metal Fabrication, Metal Fabrication Projects, Metal Fabrication Process, Metal Enclosures

When is it Appropriate to Use Laser Cutting Vs. Waterjet Cutting?

Modern metal fabricators are faced with many unique challenges, including maintaining flexibility while controlling costs with the latest projects. There’s a wide variety of equipment available and it can be tricky to stay up-to-date on the latest machine developments and how those developments can help to meet current and future operational needs. As machine technology continues to advance, there may be several ways to solve any one problem within a project, so the challenge is to fully understand each of those solutions and the unique advantages offered to remain competitive.

This week we would like to highlight some of the minor differences between water jet cutting and laser cutting. Continue reading for more information about each cutting process.

Topics: Waterjet vs Laser, Laser Cutting Capabilities, Laser Cutting Process

Quick Tips to Keep CNC Bending Costs Down With Your Next Project

In many instances, metal fabrication projects require professional pipe or tube bending services. There’s a good chance that there’s a local bending company in your area that can meet the needs of your project; however, just because a company can meet your specifications, it doesn’t mean you should request a quote immediately, especially if you want to keep costs down.

That being said, there are a few simple tips to help save money on CNC bending when you’re looking for a suitable partner. Continue reading for some brief and informative suggestions to help cut costs on CNC bending projects without negatively affecting project quality.

Topics: CNC Machining, CNC Bending

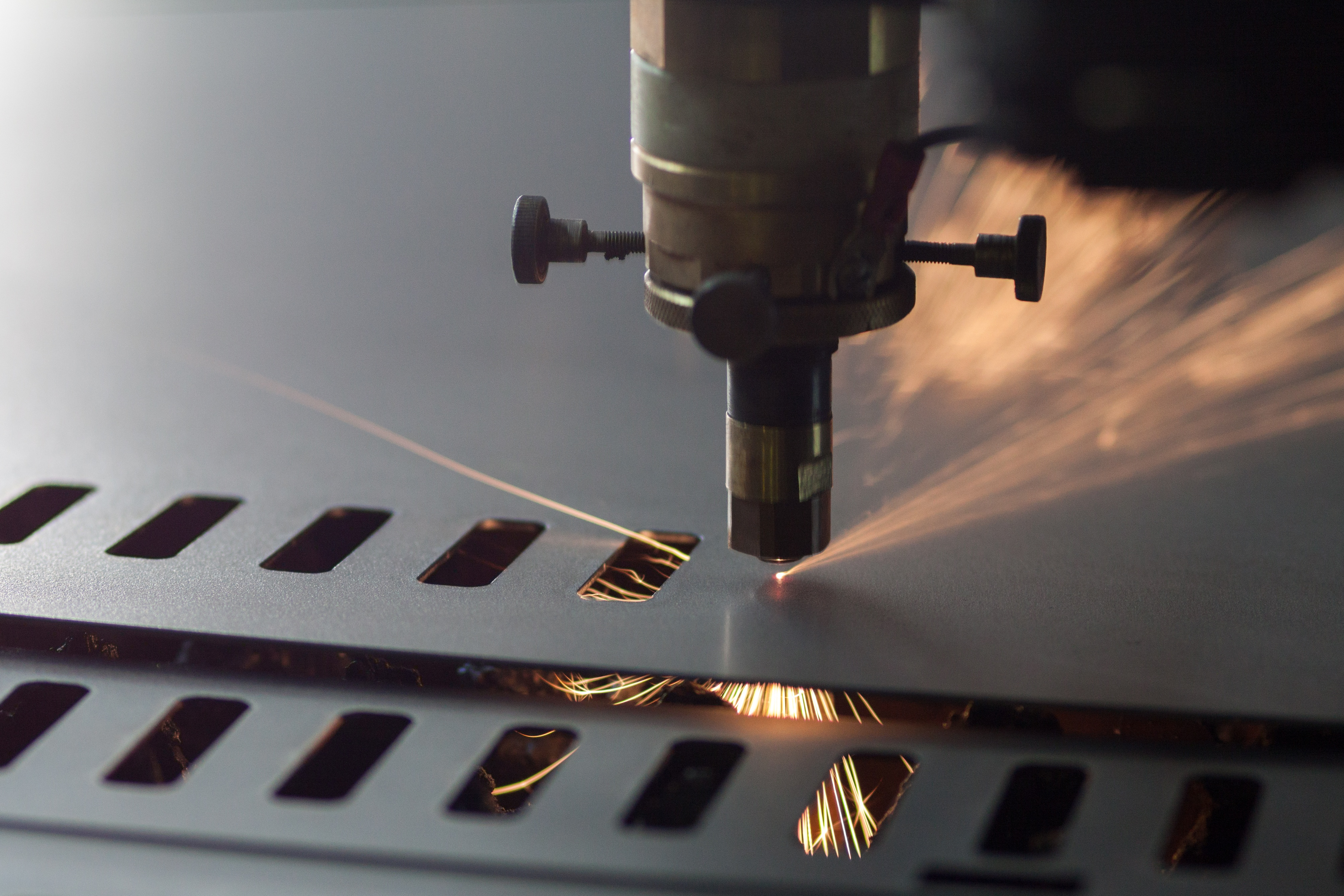

How Proper Maintenance Affects Laser Cutting Quality

Lasers can produce some of the highest quality and most accurate cuts for fabrication. However, laser cutting can only be successful when fabricators consistently perform proper maintenance on their equipment. Without proper preventative maintenance, lasers will not perform optimally. Lack of preventative maintenance can lead to lower quality, imprecise cuts and an improperly functioning machine. Fortunately, as long as you perform regular maintenance, your laser will function optimally at all times. We’ve compiled a list of the top preventative maintenance steps you can take to keep your laser in optimal condition.

Topics: Laser Cutting, Laser Cutting Services, Laser Maintenance