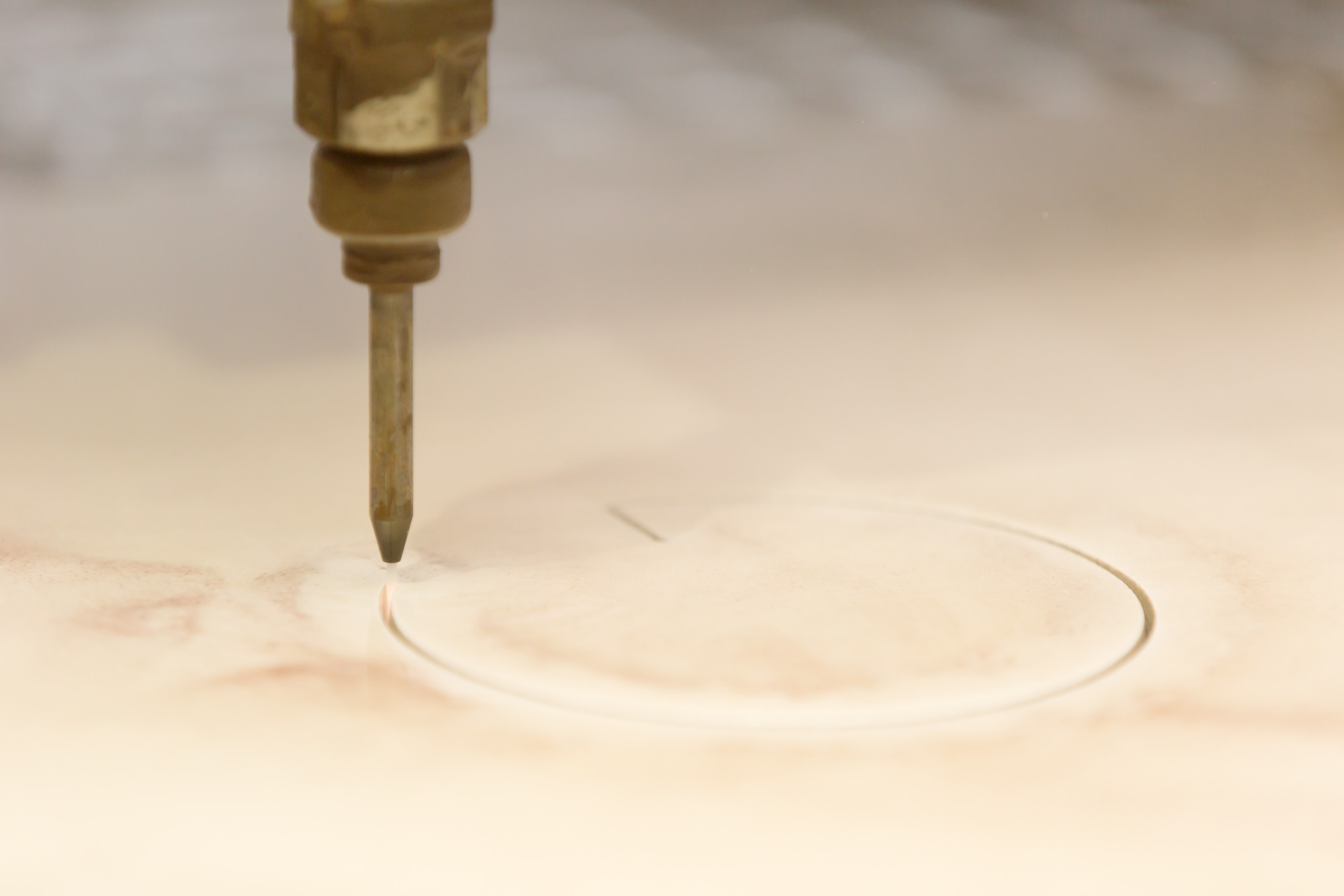

Over the years, water jet cutting has become an increasingly popular cutting method used for a wide variety of projects. Compared with other cutting methods, waterjet cutting yields cleaner results, more precision and reduced costs without some of the drawbacks associated with other methods, like thermal distortion or rough finished edges.

This blog post will help you to determine if waterjet cutting is the proper choice for your next project. We’ll cover how waterjet cutting works, its best uses, and the primary benefits.