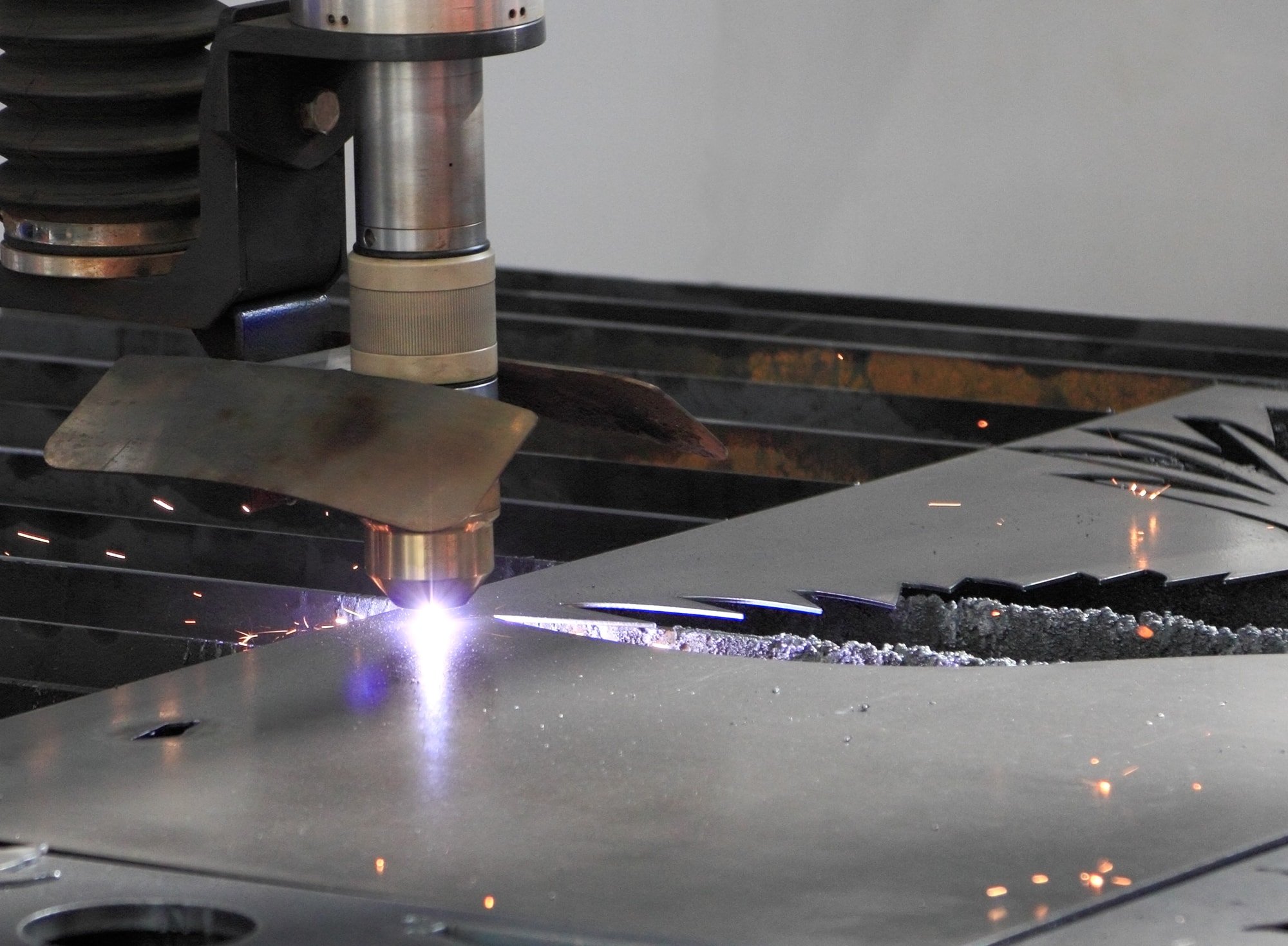

At CAMM Metals, we take immense pride in delivering top-notch services to our valued customers. To uphold our commitment to excellence, we've invested in cutting-edge technology, and today, we're excited to share how our laser tube cutting machine is revolutionizing the way we serve you. In this article, we'll explore the numerous ways this advanced machinery benefits our customers and enhances their experience with us.

1. Precision Redefined: One of the most significant advantages our laser tube cutting machine brings to the table is precision like never before. It enables us to create intricate, accurate cuts and designs with minimal tolerances. This precision ensures that your projects meet the most demanding specifications and quality standards, leaving you with peace of mind.

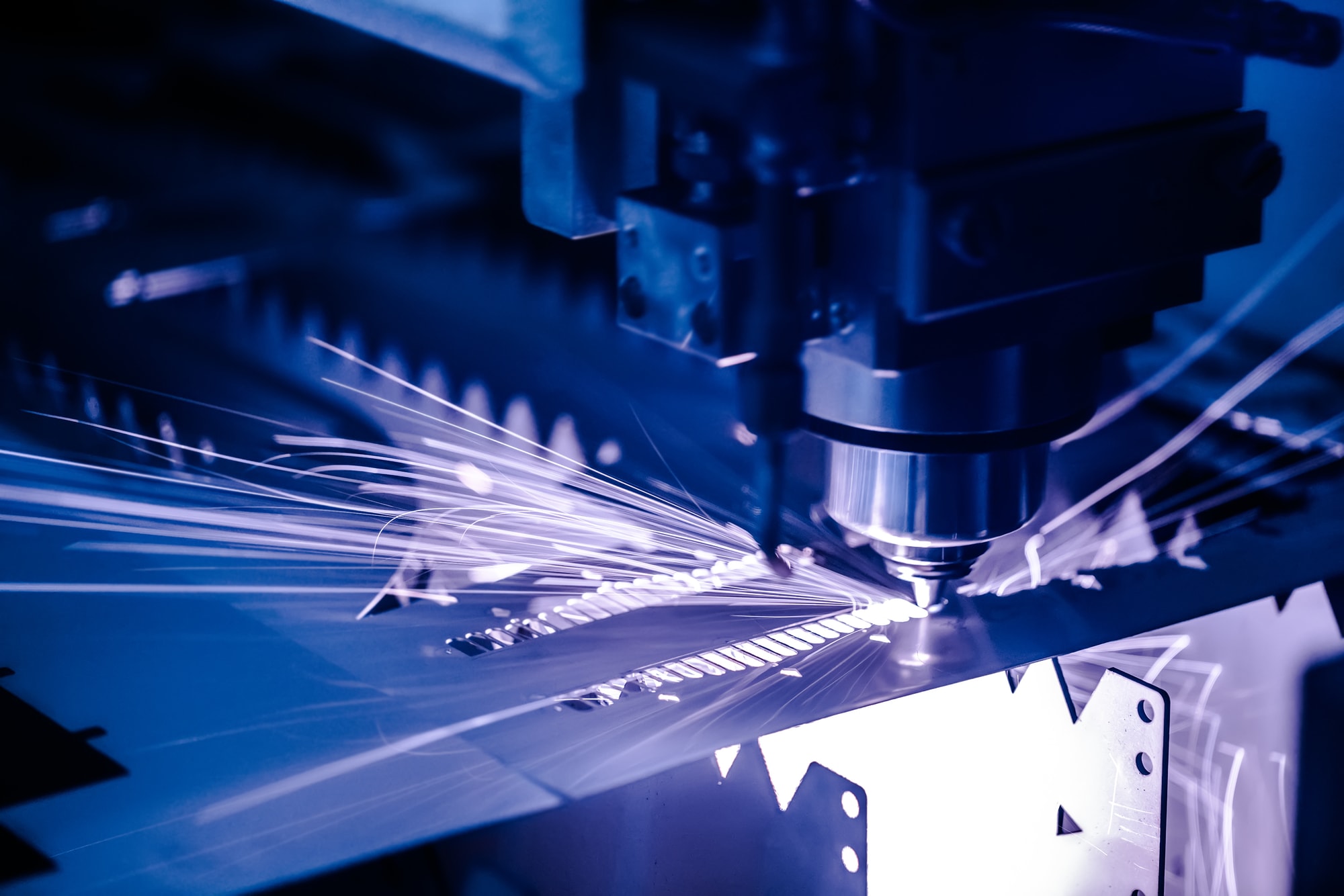

2. Faster Turnaround Times: Time is often of the essence in the world of sheet metal fabrication. With laser tube cutting, we've significantly reduced production times. This means your projects move through our shop more quickly, allowing you to meet tighter deadlines and respond swiftly to market demands.

3. Material Savings: Our commitment to eco-friendly practices extends to you. Laser tube cutting optimizes material usage, minimizing waste through precise cuts and efficient nesting. This not only reduces costs but also aligns with sustainable principles, which many of our customers appreciate.

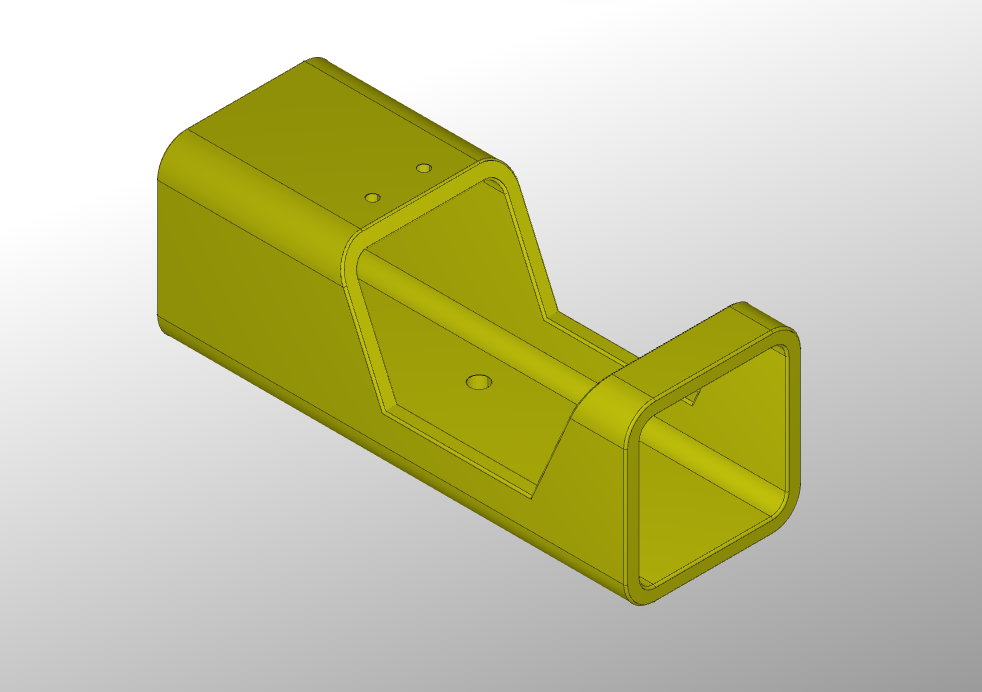

4. Versatility for Your Diverse Needs: We understand that our customers come from various industries with unique requirements. The laser tube cutting machine caters to this diversity effortlessly, handling a wide range of materials, profiles, and shapes. Whether you need components for aerospace, automotive, or architectural applications, we've got you covered.

5. Enhanced Design Freedom: Our customers often have creative and innovative designs in mind. Laser tube cutting unlocks a world of possibilities, allowing us to translate your imaginative concepts into tangible, high-precision products. This design freedom fosters collaboration and sparks innovation in your projects.

6. Quality Assurance: Quality is non-negotiable in our line of work. Laser tube cutting machines consistently deliver clean, burr-free edges and accurate cuts. This means that your parts are free from defects, reducing the need for post-processing and ensuring that you receive the highest quality products.

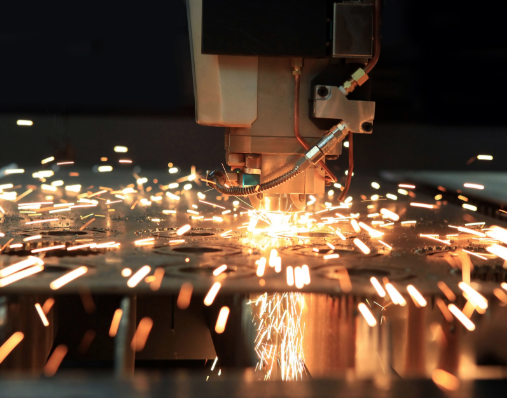

7. Exceptional Customer Service: Our investment in laser tube cutting isn't just about technology; it's about you. We're committed to providing an exceptional customer experience, and this technology empowers us to do just that. Faster turnaround times, increased precision, and superior quality all contribute to your overall satisfaction.

Conclusion: At CAMM Metals, we view our laser tube cutting machine not merely as an investment but as a service to our customers. It represents our dedication to providing you with the best possible solutions, ensuring that your projects are executed flawlessly, on time, and within budget.

We invite you to experience the advantages of our laser tube cutting capabilities firsthand. Let us elevate your sheet metal fabrication projects to new heights of precision, efficiency, and quality. Your success is our success, and with our state-of-the-art technology, we're prepared to take your projects to the next level. Contact us today to discuss how laser tube cutting can benefit your specific needs and applications.