Greetings, fellow manufacturers and enthusiasts of sheet metal fabrication! Today, we're diving into the world of precision cutting techniques, and more specifically, we'll be shining a spotlight on the incredible advantages of waterjet cutting. As the proud owner of a sheet metal job shop, I've had the privilege of witnessing firsthand the transformative power of waterjet cutting in enhancing our operations and providing our clients with top-tier results. Let's delve into what makes waterjet cutting an indispensable tool in modern sheet metal fabrication.

Exploring the Remarkable Advantages of Waterjet Cutting in Sheet Metal Fabrication

Topics: Metal Fabrication, Waterjet Cutting, stainless steel fabrication, Fabrication of Medical Devices, waterjet cutter, Inconel, Metal or Plastic, Manufacturing Design, Aerospace

4 Features That Make Waterjet Cutting The Right Choice For Your Next Metal Fabrication Project

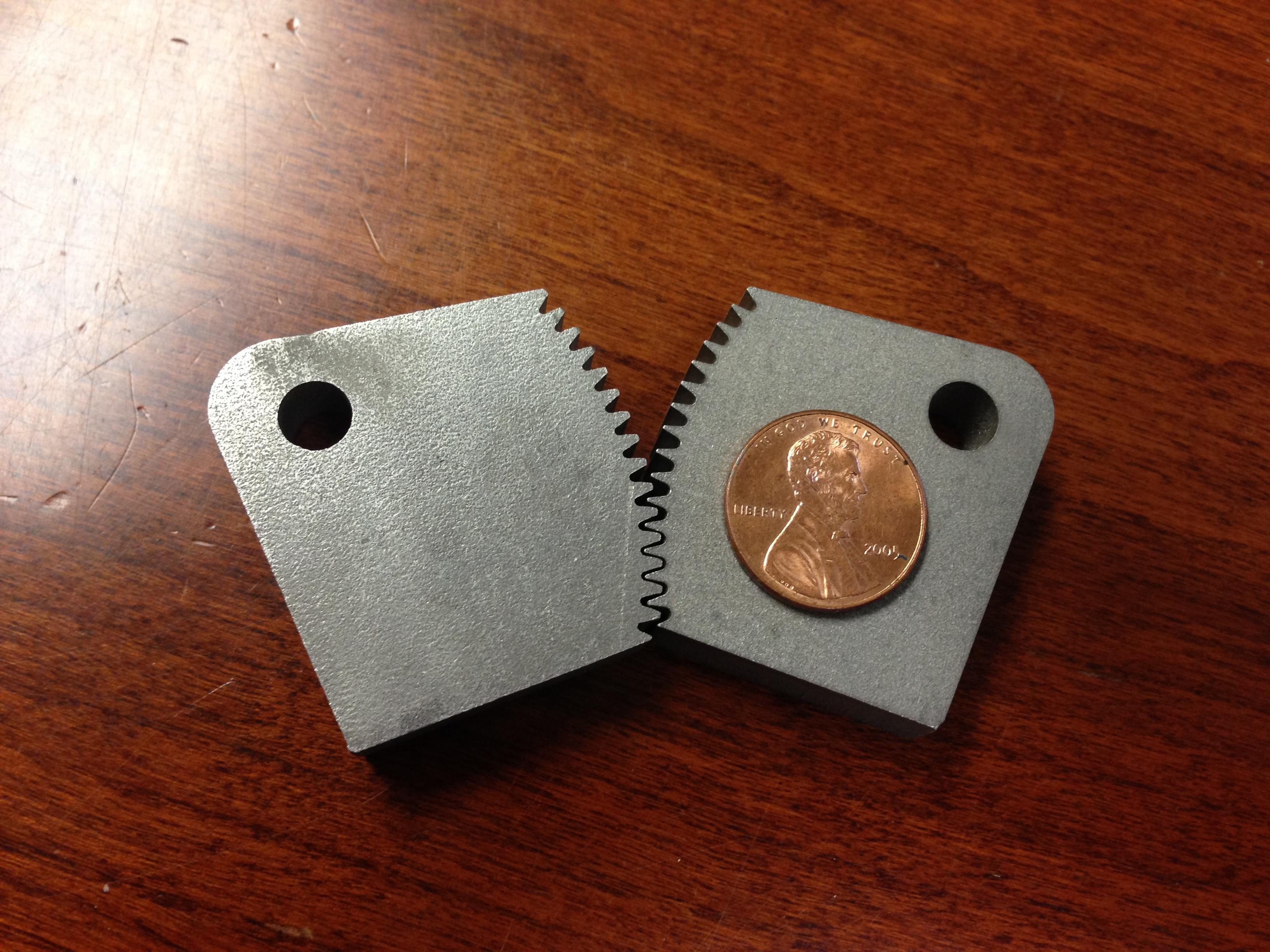

Over the years, water jet cutting has become an increasingly popular cutting method used for a wide variety of projects. Compared with other cutting methods, waterjet cutting yields cleaner results, more precision and reduced costs without some of the drawbacks associated with other methods, like thermal distortion or rough finished edges.

This blog post will help you to determine if waterjet cutting is the proper choice for your next project. We’ll cover how waterjet cutting works, its best uses, and the primary benefits.

Topics: Waterjet Cutting, Waterjet cutting services, waterjet cutter

Custom Metal Fabrication Project Spotlight: Fuel Pump Test Stands

At CAMM Metals, we're proud to have had the opportunity to manufacture 18 Fuel Pump Test Stands for an Automotive industry supplier. This project required us to use every skill, tool, and technique at our disposal. From the start, the project required 3D Engineering, Waterjet Cutting, Sawcutting, CNC Machining, Bending and Rolling, Welding and Weld Inspection, Finishing and Assembly. We like to showcase the production process because the success of any project ultimately depends on good planning, coupled with an understanding of all the techniques involved and an ability to perform all of the necessary work. Continue reading to learn about the processes involved in the custom manufacture of a fuel pump test stand and be sure to check our blog frequently for more project spotlights!

Topics: Metal Fabrication, Waterjet Cutting, Project Spotlight, Custom Metal Fabrication

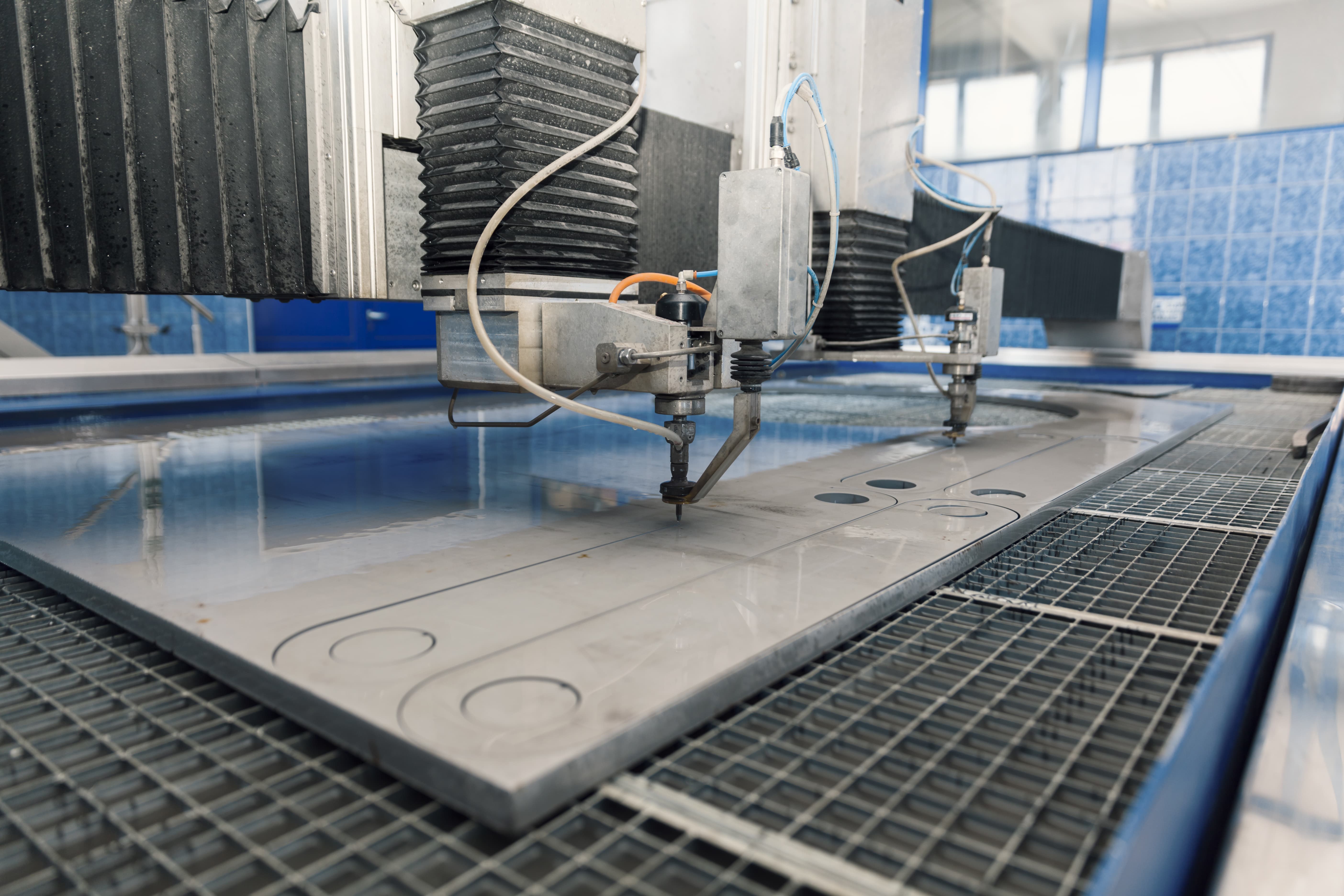

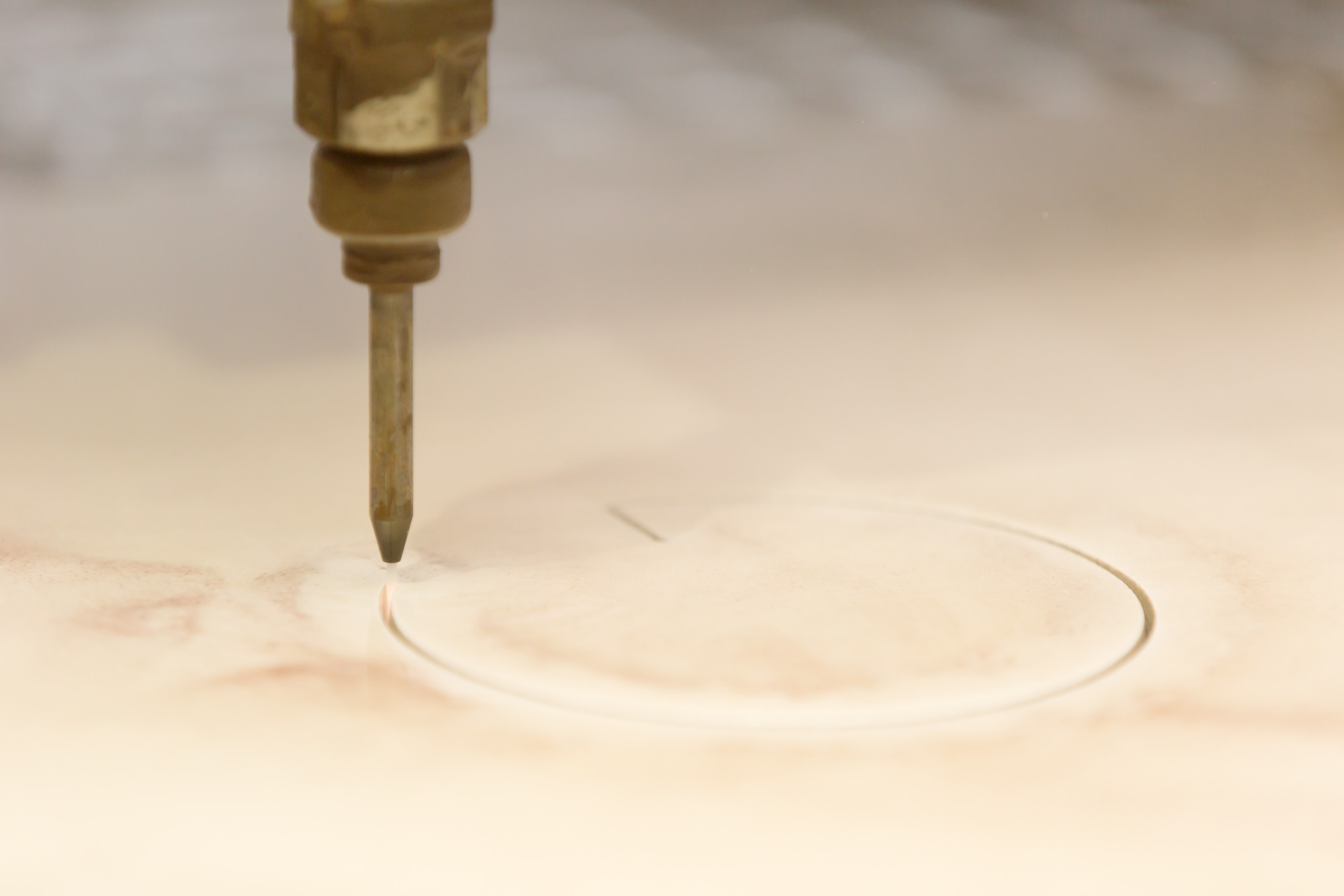

A waterjet cutting machine is a tool capable of slicing into metal and other materials using a jet of water at high velocity and pressure. Sometimes, waterjets will propel a mixture of water and an abrasive substance to improve the cut. Waterjet cutters are extremely useful tools in metal fabrication to make accurate, precise cuts without changing the intrinsic properties of the material being cut. Read below for a complete breakdown of how a waterjet cutter works.

Topics: Waterjet Cutting, Waterjet cutting services, waterjet cutter

Custom Metal Fabrication Project Spotlight: Beer Tank

Many beer fans might assume that beer tanks are coming out of some factory or huge company (or they may not even think about it all). However, the truth is much more interesting. Here in Connecticut, as a premier metal fabrication company, we have worked to service the demand for malt/beer tanks that are better welded for brewing than the typical options on the market.

For many breweries, a tank is a tank. Many tanks are stainless steel cylinders with cone shaped bottoms, imported cheaply from China; yet, there's growing demand from some brewers who want to go above and beyond the typical brewing fare.

At CAMM Metals, we're proud to have worked on the construction of a malt/beer tank. Our beer tank project required us to use every skill, tool, and technique at our disposal. From the start, the project required 3D Engineering, Waterjet Cutting, Sawcutting, CNC Machining, Bending and Rolling, Welding and Weld Inspection, Assembly and Finishing.

Continue reading to learn about the processes involved in the custom creation of a malt/beer tank and be sure to check our blog frequently for more project spotlights!

Topics: Metal Fabrication, MIG Welding, Waterjet Cutting, Project Spotlight, Forming

Waterjet cutting is a unique, highly effective process to produce clean cuts in various materials. Because there is no heat involved, it’s a great way to avoid heat damage and distortion while ensuring a smooth, clean cut. Although many people associate waterjets with metal, there are many different materials that can benefit from waterjet cutting. Here is an description of different materials that can be cut with a waterjet.

Topics: Metal Fabrication, Waterjet Cutting

As the 20th century inched towards its close, a very novel concept came into being for use in metal fabrication. Up until the 1980s, water had generally been regarded as a useful substance in industrial settings, largely for its cleaning or cooling properties. No one really thought of water as something that could rival the power a good saw, or a welding torch in terms of penetrating and cutting materials.

And yet, in the 1980s, that’s exactly what happened. That clear, harmless fluid that was used for many different purposes both personally and professionally underwent a radical transformation. When channeled through the right kind of technology, a stream of water turned from something used for pleasant showers into an incredible kinetic force capable of making clean, precise cuts through metal.

Now, in the 21st century, the use of waterjets, especially abrasive waterjets, is a well understood, widely used industrial technology. And the secret to the success of this new technique is all about physics and the use of pressure.

Topics: Metal Fabrication, Waterjet Cutting

Debunking 5 Persistent Myths About Waterjet Cutting

Waterjet cutting machines have the ability to cut through metal, plastics, and even carbon fiber without the risk of warping or distortion. Over the years, as the popularity of waterjet cutting has increased, there have been some myths and misunderstandings surrounding the technique that have left many confused as to what a waterjet machine is actually capable of. To help alleviate some of these misconceptions, we have written this post to help you better understand the process.

Topics: Metal Fabrication, Waterjet Cutting

.jpeg)