For many fabrication projects, powder coating is a better option than traditional paint. It is typically the more long-lasting and flexible option, often yielding a better finish. If you're considering powder coating for your next project, you'll want to be aware of the factors in the process that can affect the cost. Read below to learn about these factors and what you can do to safe money during the powder coating process.

CAMM Metals

Recent Posts

What Factors Affect Industrial Powder Coating Costs?

Topics: Powder Coating, Powder Coating Costs, Industrial Powder Coating

Welding aluminum can be difficult, as the metal brings about unique challenges. Because of its unstable chemical composition, it can be easily broken up under stress. Its low melting point makes it likely to warp, crack, or break. Welders can also face issues with discoloration and feedability challenges. Because of these issues, it’s important to understand the best practices for welding aluminum to reduce the risk of problematic welds. Read below to learn about the best practices for welding aluminum.

Topics: Welding Best Practices, Welding Aluminum, Welding Aluminum Best Practices

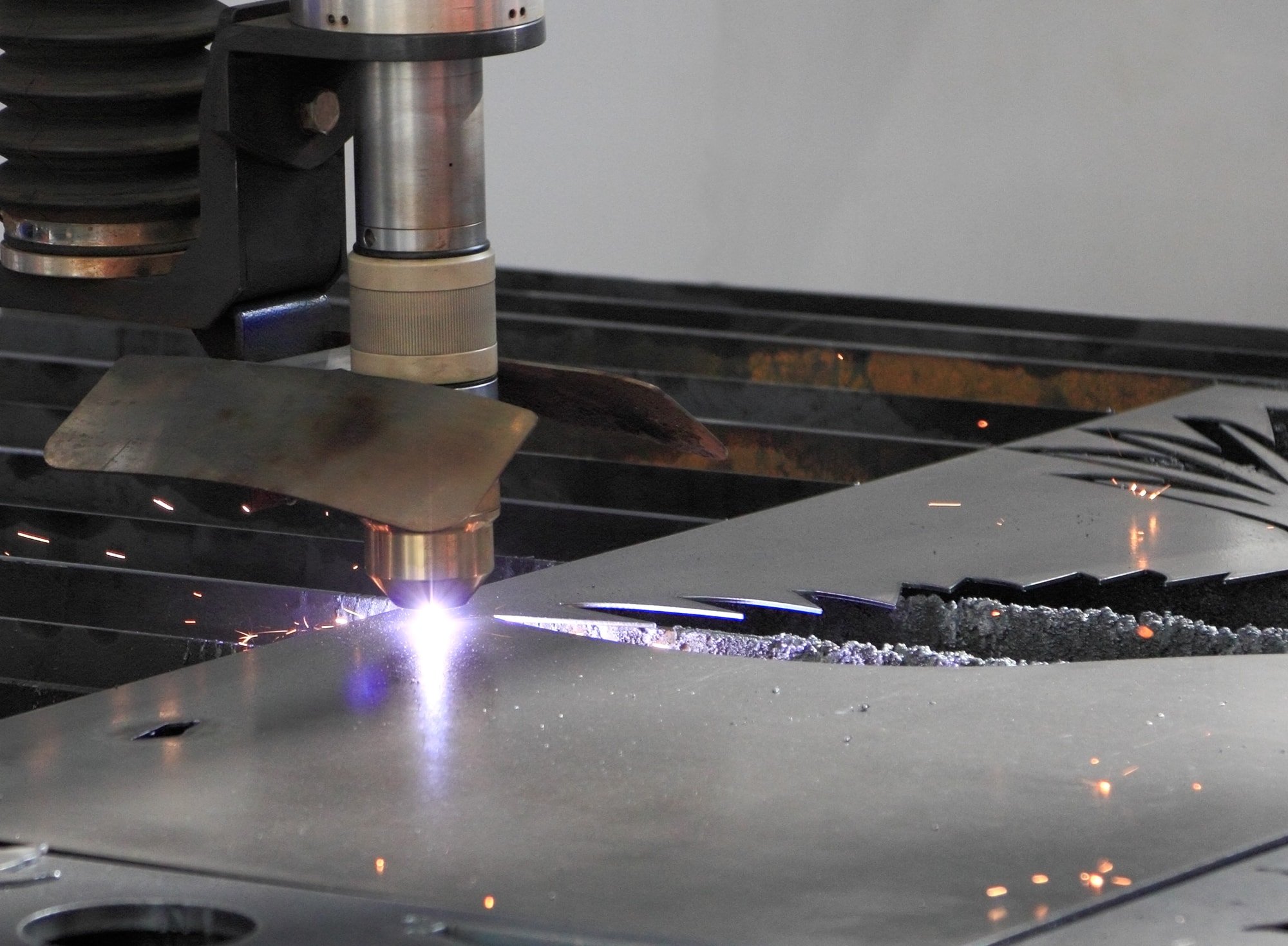

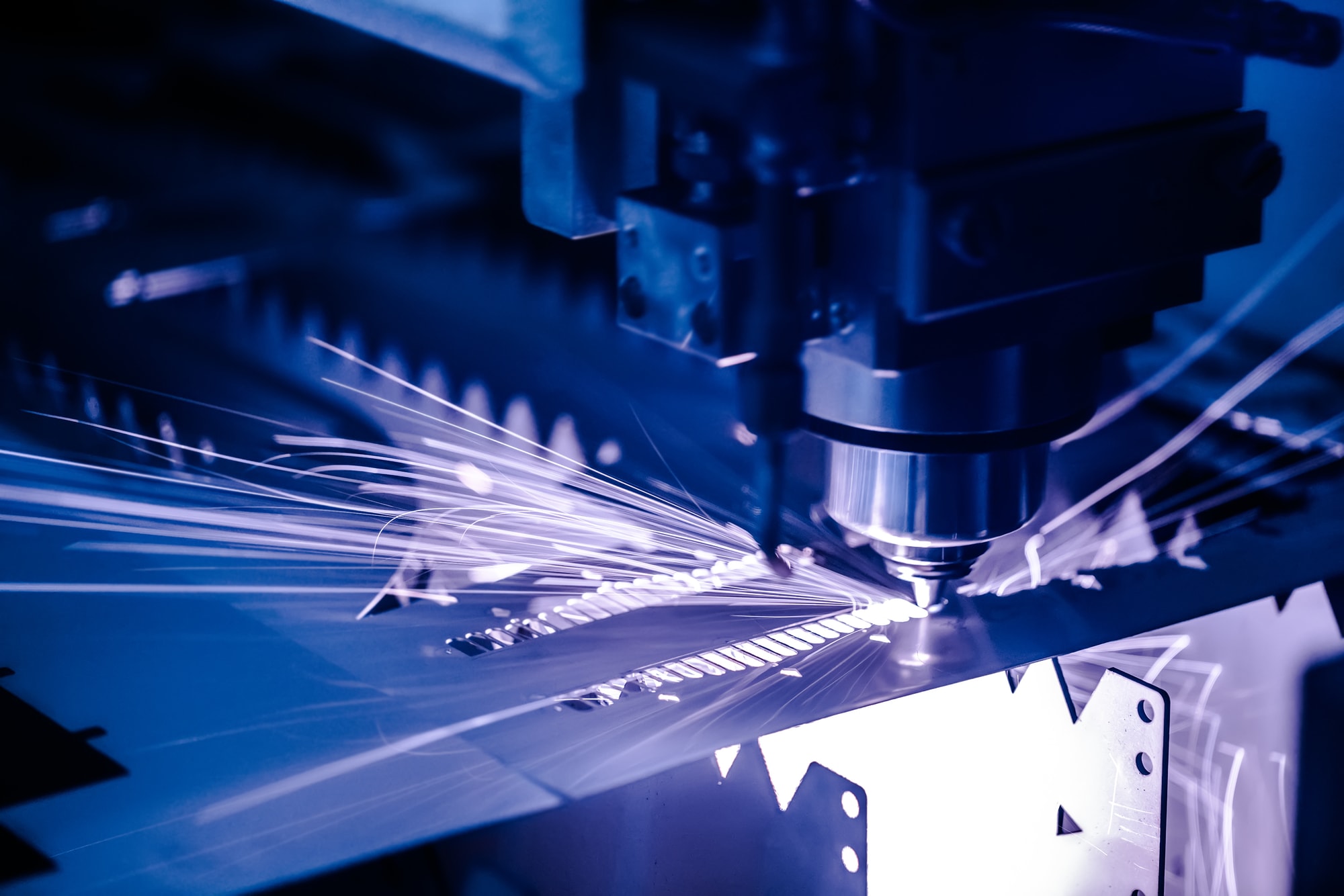

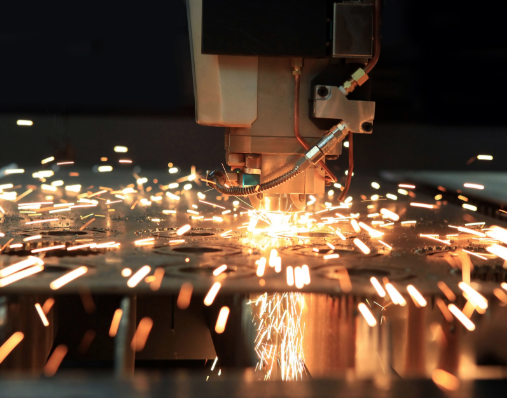

Why is Laser Cutting a Good Fit for Sheet Metal Fabrication?

Laser cutting is one of the most effective methods for cutting sheet metal. When choosing a cutting process for a sheet metal fabrication project, it’s important to consider the capabilities of the tool you choose compared to the needs of your project. For many fabrication projects using sheet metal, laser cutting is the best choice. We’ve compiled a list of reasons why laser cutters are typically a good fir for sheet metal fabrication projects.

Topics: Laser Cutting, Laser Cutting Services

A Brief Overview: How CNC Milling Machines Have Changed in Recent Years

The development of CNC machines revolutionized the manufacturing industry. Automation and programming have led to a simpler and more accurate manufacturing process. As technology has improved in recent years, CNC machines have become more advanced and are better able to carry out their functions. Read below to learn about some of the ways that CNC milling machines have changed and improved in recent years.

Topics: CNC Machining, Manufacturing Trends, CNC Machine Advances

Laser cutting is an advanced cutting process that is available for many metal fabrication projects. For many projects, it’s the best option to produce accurate, precise cuts. Fabricators often use laser cutters for intricate designs that require laser-level precision. If you’re considering purchasing a laser cutter or using a laser cutter for your next project, we’ve compiled the information you’ll need to know.

Topics: Laser Cutting, Laser Cutting Services, Laser Cutting Capabilities

CAMM Metals is Excited to Announce Our New Laser Cutting Services

CAMM Metals is excited to announce our new laser cutting services! We have officially added a Prima Power Platino Fiber Evo Laser Cutter to our facilities that is up and running. This exciting addition has expanded our overall fabrication capabilities to include laser cutting, which is one of the fastest and most efficient ways to cut metal and other materials.

Topics: Laser Cutting, Laser Cutting Services, Prima Power Platino Fiber Evo

How Can Voice Recognition Technology Improve Manufacturing Processes?

When voice recognition technology was first developed, it was largely unreliable and not suitable for most tasks. However, in the past twenty years, and especially in the past five years, voice recognition technology has improved significantly. It is now suitable for a wide variety of tasks and operations, improving efficiency and making many tasks hands-free. In the manufacturing industry, voice recognition technology can be used to find out information and carry out specific tasks. This technology has the potential to greatly improve efficiency on your shop floor.

Topics: Manufacturing Trends, Changes in Manufacturing, Voice Recognition

What are the Benefits of Powder Coating for Steel Fabrication?

When considering the finish for your fabrication project, there are several options to choose from, including powder coating and paint. Paint is the more traditional approach, but comes with many limitations in color and finish. Powder coating is often the more advanced option for finishing your metal fabrication project and can often be provided at the same cost of paint. According to the Powder Coating institute, the primary benefits of powder coating are a quality appearance, improved durability, and reduced environmental impact of your products. These benefits are just a few of the many advantages to choosing powder coating for your next stainless steel fabrication project.

Topics: stainless steel fabrication, Powder Coating, Powder Coating Benefits

8 Quick Tips to Save Money on Sheet Metal Fabrication

Completing a sheet metal fabrication project is a costly process. The design, the possible prototype, the actual production process, and the finishing processes all have associated fees. In addition to the work that goes in to your project, the materials themselves cost money as well. To save money, you’ll need a well-optimized design and a cost-saving plan. We’ve compiled a list of tips that can help you save money on your next metal fabrication project.

Topics: Custom Sheet Metal Fabrication, metal fabrication costs, Saving Money on Metal Fabrication

Laser cutting is an extremely useful method of cutting through materials for manufacturing purposes. Not only can laser cutters produce highly precise and accurate cuts, but they are very versatile, as they are able to cut through a wide variety of materials. We’ve compiled a list of the top questions that manufacturers have about laser cutters to help explain how they work and what they can offer manufacturers.

Topics: Laser Cutting, Laser Cutting Services