Welcome to our sheet metal job shop, where innovation meets precision to shape the future of metal fabrication. Today, we're diving into the world of laser cutting technologies and exploring the remarkable advantages that fiber laser cutting holds over traditional CO2 laser cutting methods.

Revolutionizing Sheet Metal Fabrication: The Advantages of Fiber Laser Cutting Over CO2 Laser Cutting

Topics: Custom Sheet Metal Fabrication, Fabrication of Medical Devices, Laser Cutting, Waterjet vs Laser, Green Energy Industry, Reducing Lead Times, Laser Cutting Capabilities, Laser Maintenance, Fiber Laser Cutting

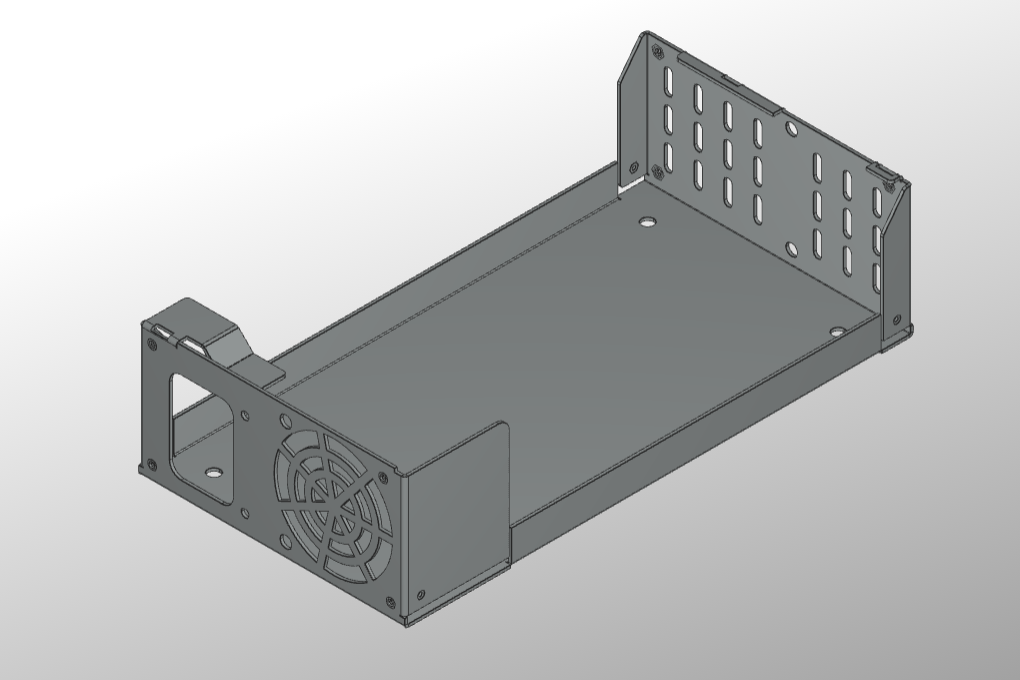

Enhancing Precision and Efficiency: How Sheet Metal Fabricators Leverage 3D CAD Files to Produce Quality Parts

Topics: Metal Fabrication, Steel Fabrication, CAD Models in Manufacturing, Engineering Designs, Custom Sheet Metal Fabrication, Fabrication of Medical Devices, Custom Metal Fabrication, Press Braking, Laser Cutting, Manufacturing Design, Changes in Manufacturing, Laser Cutting Capabilities, Metal Enclosures, Fiber Laser Cutting

Adhering to the guidelines associated with design for manufacturing (DFM) ensures that a sheet metal design flows through the processes without issues. This ultimately helps to improve lead times and lowers the overall project cost. Fortunately, there are numerous techniques you can use to increase the chances your sheet metal part is ready for manufacturing.

Topics: Custom Sheet Metal Fabrication

8 Quick Tips to Save Money on Sheet Metal Fabrication

Completing a sheet metal fabrication project is a costly process. The design, the possible prototype, the actual production process, and the finishing processes all have associated fees. In addition to the work that goes in to your project, the materials themselves cost money as well. To save money, you’ll need a well-optimized design and a cost-saving plan. We’ve compiled a list of tips that can help you save money on your next metal fabrication project.

Topics: Custom Sheet Metal Fabrication, metal fabrication costs, Saving Money on Metal Fabrication

6 Factors to Consider When Choosing Between Aluminum or Stainless Steel Fabrication

Stainless steel and aluminum fabrication processes are put to use to produce parts and structures for a wide range of industries. Aluminum is often used in the marine equipment industry thanks to its light weight and resistance to corrosion.

While it’s technically not considered a non-ferrous metal, stainless steel is also valued due in part to its lack of magnetism and its versatile applications in the industrial environment. This post provides an overview of six factors to consider when you’re determining whether aluminum or stainless steel materials are best suited to your next project’s needs.

Topics: Metal Fabrication, Custom Sheet Metal Fabrication, Custom Metal Fabrication

How Custom Sheet Metal Fabrication Benefits the Medical Industry

Sheet metal fabrication is a broad term referring to cutting, shaping, and molding sheet metal into a final product. However, custom sheet metal fabrication involves a non-standard component or unique metal product of some sort. Custom sheet metal fabrication is important to the medical industry, as it can help create tools that carry out very precise and specific functions. Read below for more information on the application of this process in the medical industry.

Topics: Custom Sheet Metal Fabrication, Fabrication of Medical Devices, Metal Fabrication for the Medical Industry