Laser cutting is an advanced cutting process that is available for many metal fabrication projects. For many projects, it’s the best option to produce accurate, precise cuts. Fabricators often use laser cutters for intricate designs that require laser-level precision. If you’re considering purchasing a laser cutter or using a laser cutter for your next project, we’ve compiled the information you’ll need to know.

How Do They Work?

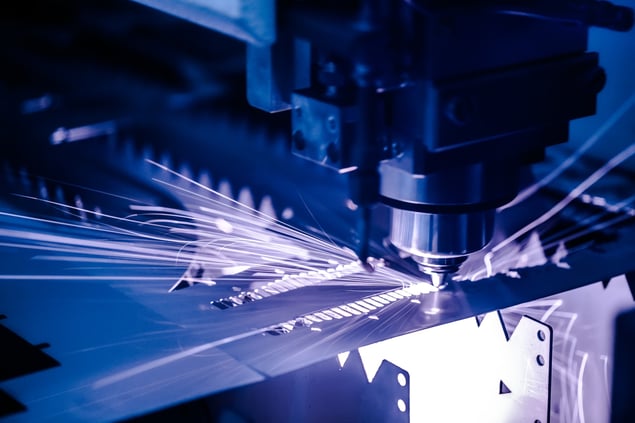

Laser cutting involves a high-powered highly focused laser. The machine runs the laser beam through the material, piercing a hole. Once there is a hole in the material, the laser cuts through, leaving a clean cut with a smooth finish. Laser cutters sometimes use a pulse laser beam, where the cut is delivered in the pulses of the laser. Other times, laser cutters use a continuous wave, where the beam is kept focused on the material until the cut is delivered. In both cases, laser cutters use high-powered lasers to pierce through materials and create precise cuts.

Which Materials Can Lasers Cut Through?

Laser cutters are highly versatile machines. They can cut through a wide variety of materials including ceramics, plastics, and various types of metals. Laser cutters are a great choice for cutting through:

- Stainless Steel

- Steel

- Aluminum

- Nickel

- Brass

- Copper

What is the Quality of the Cut?

Because this machine makes cuts with a laser, some people worry about the HAZ and overall quality of the cuts produced. However, the heat activated zone is very minimal when using a laser cutter. Additionally, laser cutters involve a focused, narrow beam that ensures highly precise cuts. Because they are programmed by a computer and cut with such precision, the cuts are highly accurate as well. During the cutting process, the laser beam smoothes the cut, creating an overall high quality cut that will be reliable in manufacturing process and allows for intricate designs.

How Does it Compare to Other Cutting Processes?

Laser cutting is an extremely energy efficient process. In fact, it uses significantly less power than most other cutting systems. Laser cutters also produce more accurate and precise cuts than other cutting mechanisms. It is a faster process than cutting processes such as waterjet cutting. Additionally, the cutting process is much safer for the operator than a free running blade.

Will Laser Cutters Damage the Materials Being Cut?

Because lasers use heat to produce cuts, many people worry that the heat-activated zone will lead to damage to the material being cut. However, laser cutters do not damage materials. They are highly precise and focused, making the heat damage very minimal. Additionally, the laser smoothes the cut as it is cutting, meaning that there is no damage done to the surrounding area of the cut.

Which Industries Can Benefit From Laser Cutting?

The manufacturing industry obviously benefits from laser cutters for production. The precise and accurate cuts allow manufacturers to use laser cutters to create parts for many different industries including:

- Automotive

- Aerospace

- Semiconductor

- Electronics

- Medical

- Original Equipment Manufacturers

Why Choose Laser Cutting?

There are many different benefits to using a laser cutter during the manufacturing process. They will lead to shorter lead times than many other cutting processes. They are highly precise, allowing for accurate cuts and intricate designs. They create consistent cuts, able to create identical products for mass manufacturing. Laser cutters are more energy efficient, helping manufacturers go green and save money on their energy bill. They are also highly versatile, able to cut through a wide variety of materials and produce many different designs with varying levels of intricacy. Lastly, laser cutters have less finishing requirements than other, less precise cutting processes. To learn more about the advantages of laser cutting metal, click here. When you choose laser cutting for your project, you can expect a fast cutting process and a high quality cut.

CAMM Metals | CT Laser Cutting Services

It's crucial to do your research when choosing a metal fabrication, as not all companies are capable of completing the same quality of work. CAMM Metals has years of experience, honing our skills across the board to deliver a quality product and measurable bottom line value to our customers.