If you’re searching for a metal fabrication company to help complete your latest project, it’s essential that you understand how to acquire an accurate estimate.

If you’re saddled with a vague understanding of your project, it’s possible that you could get burned on an estimate. Whether you’re seeking to hire a team for a small done-in-a-day welding project or a nuanced and lengthy metal fabrication project, steer clear of these mistakes to get the most accurate estimate.

CAMM Metals

Recent Posts

4 Common Mistakes to Avoid When Obtaining a Metal Fabrication Quote

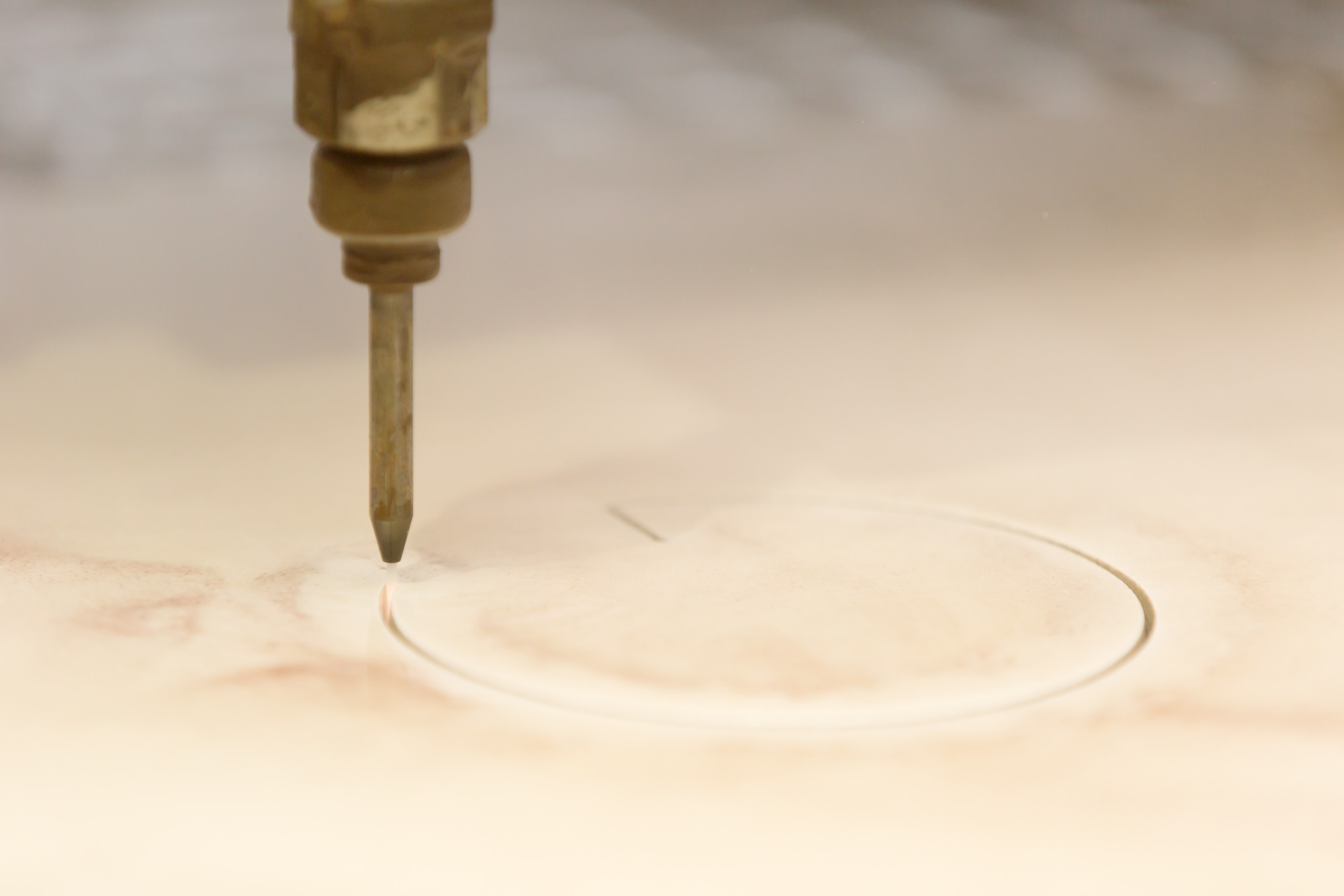

A waterjet cutting machine is a tool capable of slicing into metal and other materials using a jet of water at high velocity and pressure. Sometimes, waterjets will propel a mixture of water and an abrasive substance to improve the cut. Waterjet cutters are extremely useful tools in metal fabrication to make accurate, precise cuts without changing the intrinsic properties of the material being cut. Read below for a complete breakdown of how a waterjet cutter works.

Topics: Waterjet Cutting, Waterjet cutting services, waterjet cutter

How Tolerances Affect Custom Metal Fabrication Projects

Tolerance is a crucial aspect of metal fabrication projects— and it remains one of the most examined factors for establishing manufacturing quality. Over the years, as tolerance expectations have increasingly more stringent, the more challenging the manufacturing process becomes for a given part. Even though technologies involved in water jet cutting, welding, and machining have continued to develop, especially tight tolerances are still not universally achievable by any given shop.

Tolerances are important to the manufacturing process as they determine how well a part will fit in final production and, as a result, how stable the final product will be. Essentially, tolerances can refer to mechanical fit, fit up, deviations from perfect straightness or accuracy of assembly. This post will provide a brief overview of how tolerance affects custom metal fabrication projects.

Topics: Tolerances, Custom Metal Fabrication, Metal Fabrication Projects

How Custom Sheet Metal Fabrication Benefits the Medical Industry

Sheet metal fabrication is a broad term referring to cutting, shaping, and molding sheet metal into a final product. However, custom sheet metal fabrication involves a non-standard component or unique metal product of some sort. Custom sheet metal fabrication is important to the medical industry, as it can help create tools that carry out very precise and specific functions. Read below for more information on the application of this process in the medical industry.

Topics: Custom Sheet Metal Fabrication, Fabrication of Medical Devices, Metal Fabrication for the Medical Industry

4 Things to Know About Manufacturing Medical Devices

Medical devices are very important tools. They must be created with immense accuracy and precision because they have such an important purpose. In order to create proper medical devices, there are certain steps that need to be taken. In order to ensure that your manufacturer creates the devices to your exact specifications, there are certain considerations you should take into account. Here are some things you should know about making medical devices.

Topics: Fabrication of Medical Devices, Metal Fabrication for the Medical Industry

Sandblasting involves propelling small, granulated pieces, usually sand, at a high speed in order to clean or etch a surface. Many metal fabrication companies make use of this technique because of its effectiveness and wide application. Here are some of the benefits of sandblasting.

Simplicity

Sandblasting is a fairly simple job. Although a professional needs to do the job, it’s not a particularly long or strenuous process. Professionals will lay a tarp underneath the surface being blasted, making cleanup quick and easy. At the end of the process, simply remove the extra material and clean off the tarp.

Topics: Metal Fabrication, Sandblasting

Metal fabrication is an important and versatile service. Many industries that you wouldn't expect rely on metal fabrication in order to function and keep operations running smoothly. Here is a list of various industries that depend on metal fabrication.

Custom Metal Fabrication Project Spotlight: Beer Tank

Many beer fans might assume that beer tanks are coming out of some factory or huge company (or they may not even think about it all). However, the truth is much more interesting. Here in Connecticut, as a premier metal fabrication company, we have worked to service the demand for malt/beer tanks that are better welded for brewing than the typical options on the market.

For many breweries, a tank is a tank. Many tanks are stainless steel cylinders with cone shaped bottoms, imported cheaply from China; yet, there's growing demand from some brewers who want to go above and beyond the typical brewing fare.

At CAMM Metals, we're proud to have worked on the construction of a malt/beer tank. Our beer tank project required us to use every skill, tool, and technique at our disposal. From the start, the project required 3D Engineering, Waterjet Cutting, Sawcutting, CNC Machining, Bending and Rolling, Welding and Weld Inspection, Assembly and Finishing.

Continue reading to learn about the processes involved in the custom creation of a malt/beer tank and be sure to check our blog frequently for more project spotlights!

Topics: Metal Fabrication, MIG Welding, Waterjet Cutting, Project Spotlight, Forming

6 Benefits of Galvanizing in Metal Fabrication Projects

Galvanizing is a process used by many reputable metal fabricators. It allows fabricators to properly protect steel using an effective and efficient process. There are many reasons to choose galvanizing over other protective coating methods. Here are the benefits of galvanizing for metal fabrication projects.

Topics: Metal Fabrication, Galvanization, Galvanization Services

There are many misconceptions when it comes to metal manufacturing. For people outside the industry, these assumptions are believed because they are not presented with better evidence. However, even within the industry there are certain myths that seem to persist. Here is a discussion of many of the prominent myths in metal manufacturing that are untrue.