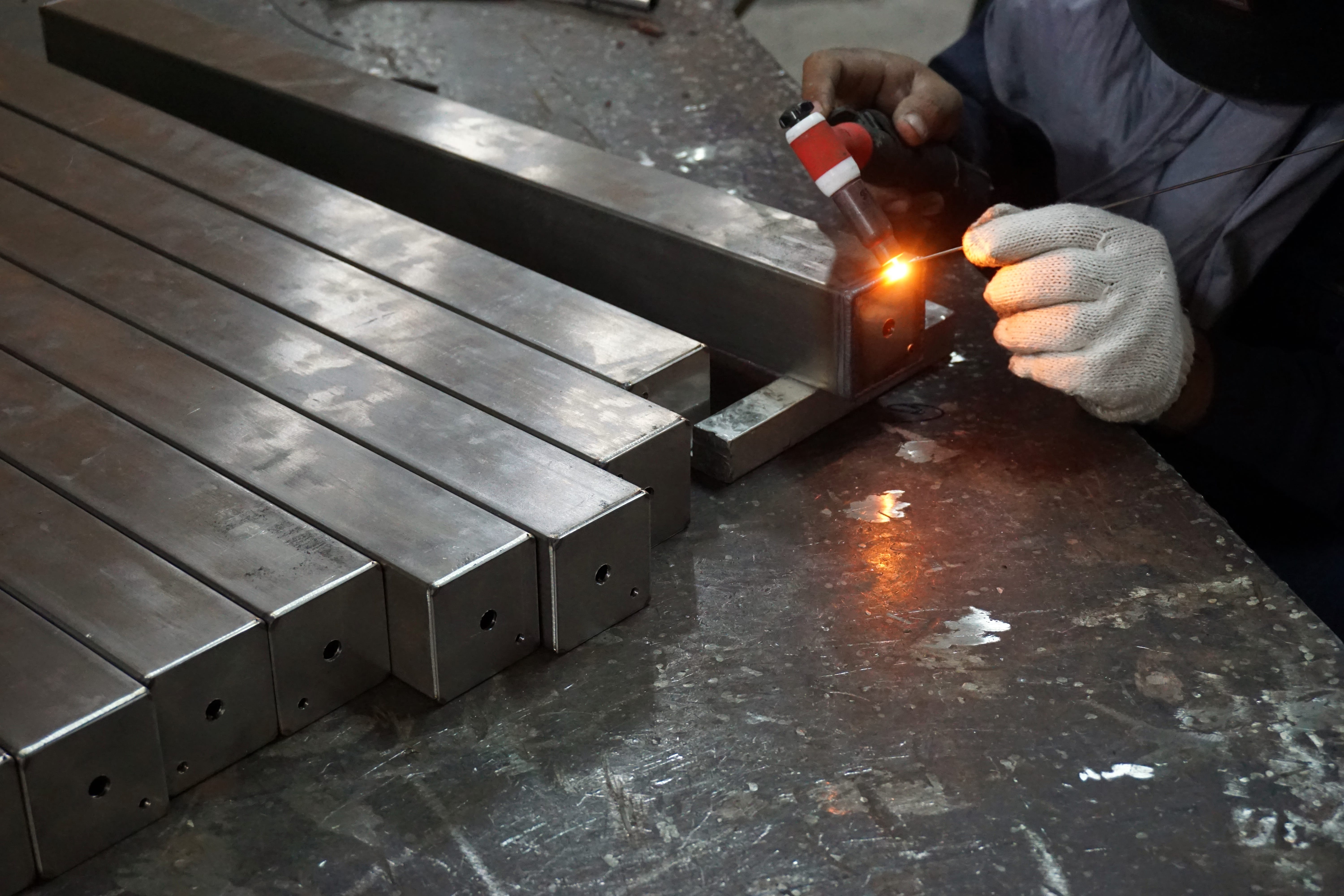

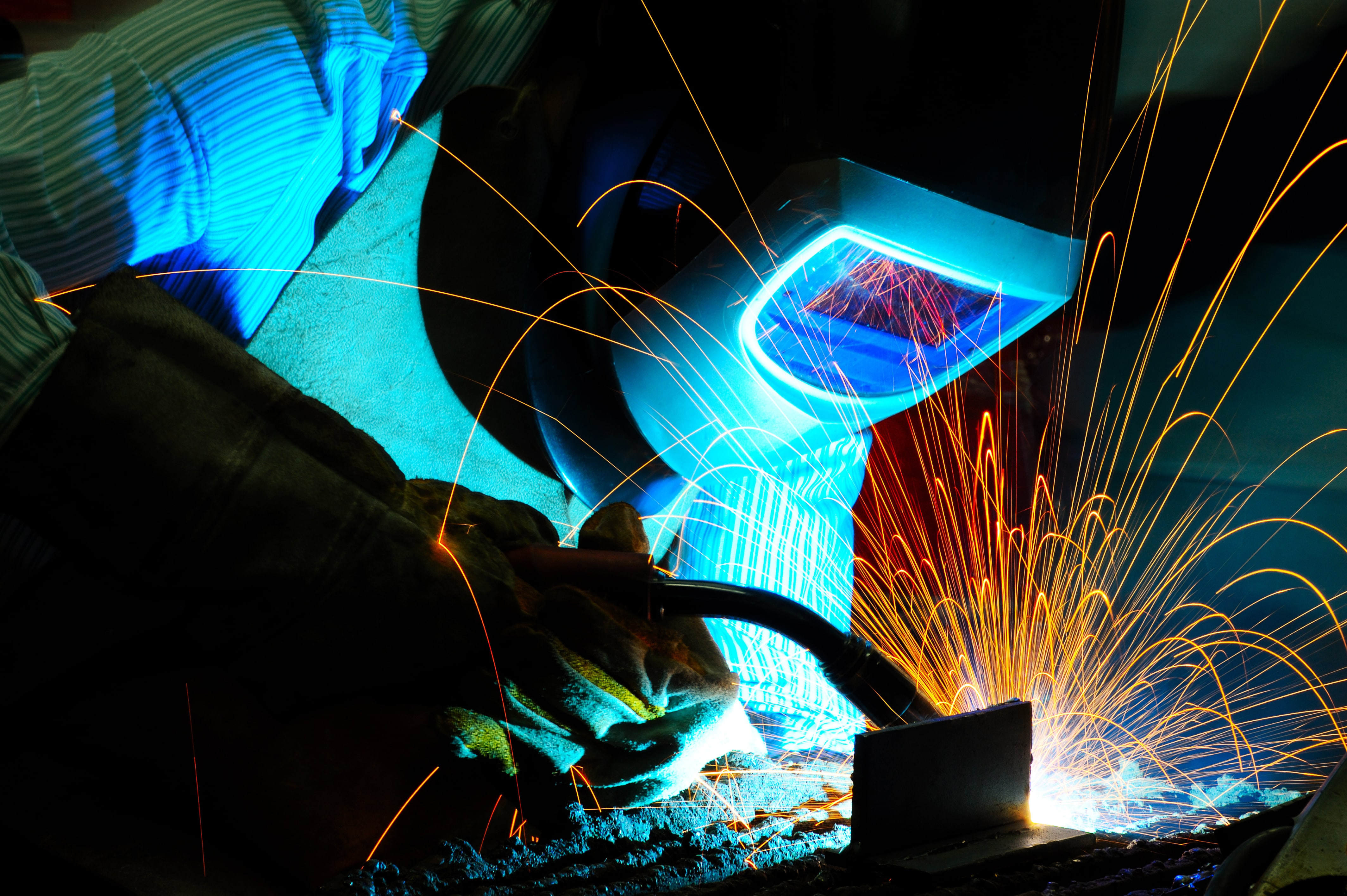

During the welding process, the weld metal and the adjacent base metal will expand and contract throughout the heating and cooling cycle. During these cycles, it’s inevitable that some distortion will occur due to the movement of the metal. However, it’s important to take steps to minimize this distortion whenever possible. Here are some tips to minimize welding distortion.

CAMM Metals

Recent Posts

Topics: Metal Fabrication, Welding, Welding Distortion

Why Should One Metal Fabrication Company Handle My Entire Project?

Metal fabrication is a very involved process. From cutting to welding to polishing, there are many different operations involved in the metal fabrication process. Although there are different companies that can handle different parts of the job, for the best product it’s better to deal with a single, all-encompassing metal fabrication company. Here are some reasons why you should use one metal fabrication company to handle your entire project.

Topics: Metal Fabrication, local metal fabricator

Waterjet cutting is a unique, highly effective process to produce clean cuts in various materials. Because there is no heat involved, it’s a great way to avoid heat damage and distortion while ensuring a smooth, clean cut. Although many people associate waterjets with metal, there are many different materials that can benefit from waterjet cutting. Here is an description of different materials that can be cut with a waterjet.

Topics: Metal Fabrication, Waterjet Cutting

Powder Coating vs. Painting Metal: Which One is Better?

There are different options to consider when deciding on proper coating for metal product. Powder coating involves the application of a dry powder that settles with the application of heat from an oven. Painting involves the application of liquid paint with a pump, spray or other pressurized applicant. Both of these methods are viable options to coat a metal product, but come with advantages and disadvantages. Below is a comparison of the different aspects of powder coating and painting to help you evaluate which option is best for you.

Topics: Painting Metal, Powder Coating

What are the Benefits Of Working with a Local Metal Fabricator?

Working in the heavy industry, especially an area that requires some kind of metal fabrication means the pursuit of two characteristics; reliability and efficiency. When you have a product or component that needs to be manufactured for your business, you need to make sure that that it is created in a way that is both cost-effective, and easily repeatable.

Topics: Metal Fabrication, Manufacturing, local metal fabricator

As the 20th century inched towards its close, a very novel concept came into being for use in metal fabrication. Up until the 1980s, water had generally been regarded as a useful substance in industrial settings, largely for its cleaning or cooling properties. No one really thought of water as something that could rival the power a good saw, or a welding torch in terms of penetrating and cutting materials.

And yet, in the 1980s, that’s exactly what happened. That clear, harmless fluid that was used for many different purposes both personally and professionally underwent a radical transformation. When channeled through the right kind of technology, a stream of water turned from something used for pleasant showers into an incredible kinetic force capable of making clean, precise cuts through metal.

Now, in the 21st century, the use of waterjets, especially abrasive waterjets, is a well understood, widely used industrial technology. And the secret to the success of this new technique is all about physics and the use of pressure.

Topics: Metal Fabrication, Waterjet Cutting

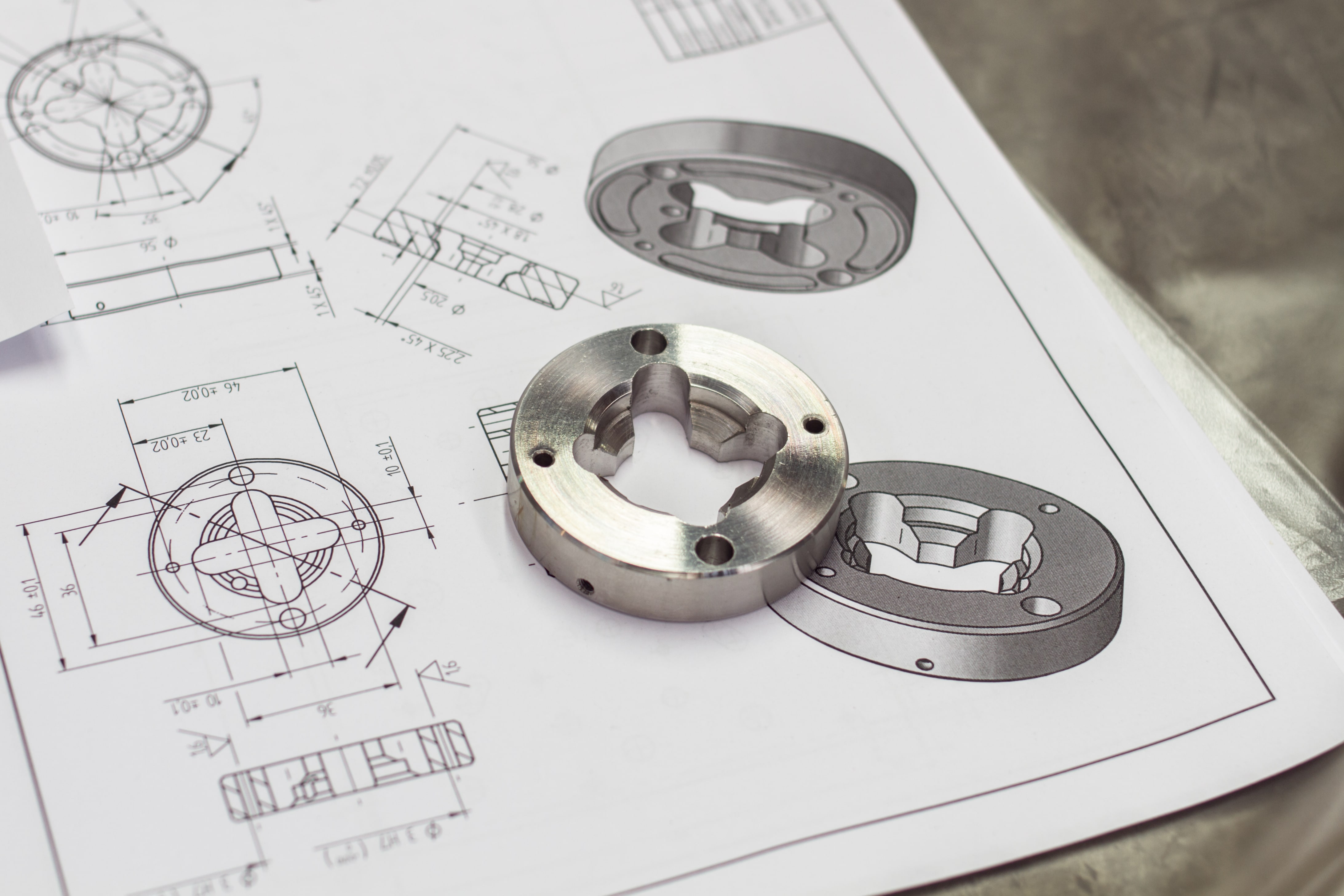

CNC machining has become one of the most important and efficient means of handling metal fabrication tasks in modern American industry. This is because the technology itself is a combination of sophisticated software programming married to advanced mechanical engineering to produce a system known as “computer numerical control,” or CNC.

Topics: Metal Fabrication, CNC Machining

Common Mistakes to Avoid With Stainless Steel Fabrication

Stainless steel fabrication is a complicated process. It’s important that it’s done right in order to create quality products. There are many mistakes that a steel fabricator could make, both on a production level and on a larger scale. Read below to learn about the common mistakes that you should avoid with stainless steel fabrication.

Warning Signs To Watch For When Seeking a Metal Fabrication Company

Establishing and growing successful manufacturing partnerships can be a challenge, especially when you’re on the hunt for a metal fabrication partner. Some companies prioritize bulk production runs at a lower cost, while others focus on smaller business with more options for customization.

Simply put, it’s a wast of customer time and money if the partnership isn’t mutually beneficial.

This post provides a brief overview of several red flags, indicating the need to be cautious when researching a metal fabrication partner. At CAMM metals, you can always request a quote and we’re happy to guide you through both your project and the manufacturing process with you.

Topics: Metal Fabrication

4 Important Questions to Help Find a Reputable Metal Fabrication Company

Finding the right metal fabrication partner can be tricky due to a wide variety of factors. Often, metal fabrication supply partners are selected based solely on their ability to provide a low cost solution. While cost remains an important factor, it’s important to consider the fabrication company’s overall capabilities, experience, and quality. This blog post aims to help procurement professionals develop useful questions to ask potential metal fabrication companies.

Topics: Metal Fabrication

.jpeg)