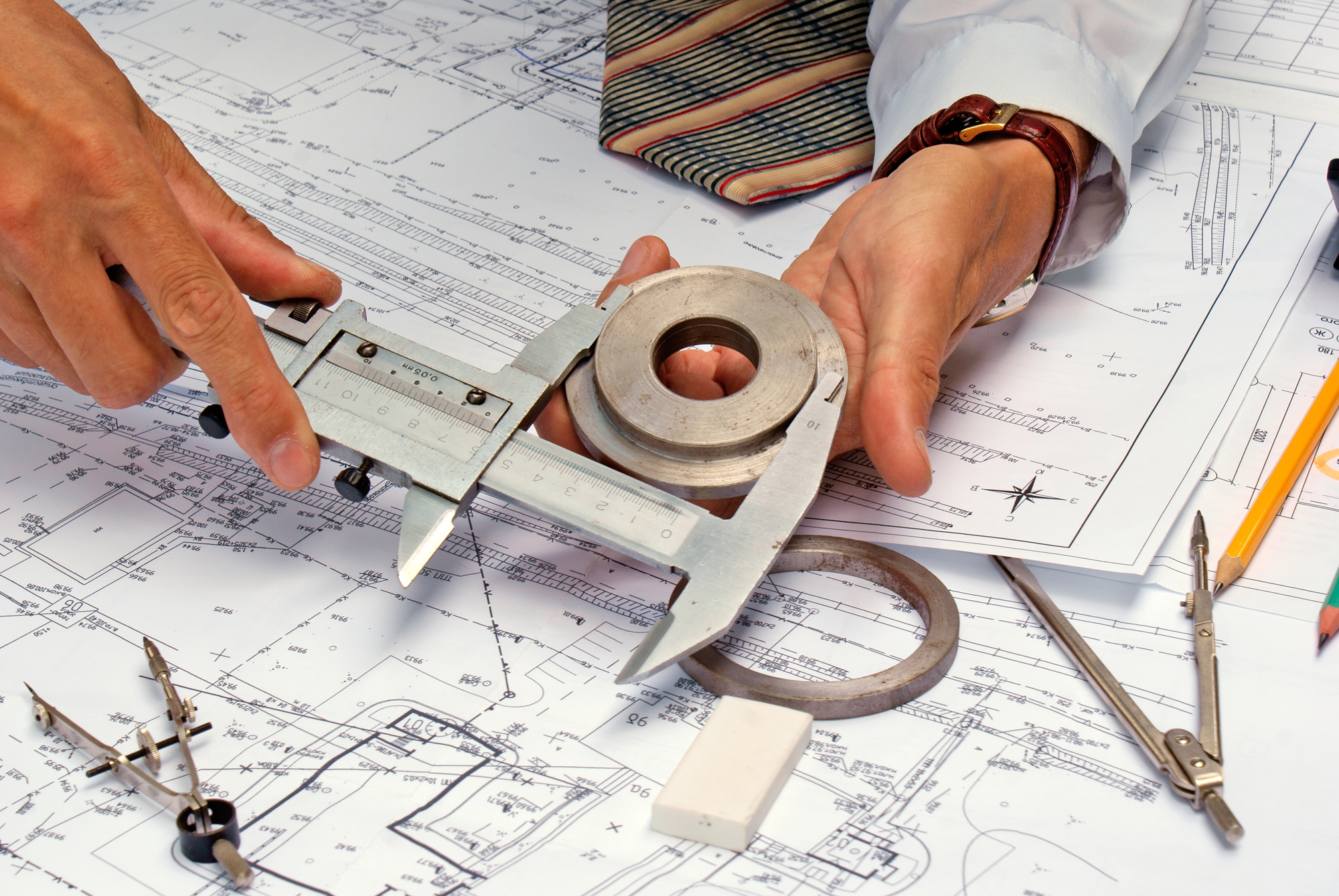

It’s not an area that gets a lot of coverage with the general public, but when it comes to design and manufacturing, in a lot of ways, “the future” arrived a couple of decades ago, and has been heavily relied on ever since. Prior to the use of CAD models in many industries, the ways that engineers, architects, designers and many other experts came up with ideas was through the use of schematics and blueprints. CAD models changed all that for the better.

The Importance of CAD Models for Metal Fabrication Projects

6 Tips to Optimize Your Design for a Metal Fabrication Project

When creating a design for metal fabrication, it’s important to make sure your fabricator will be able to easily translate the design into your desired product. In order to create a useful design, there are certain considerations you should take into account. Here are some tips to optimize your design for metal fabrication.

4 Reasons to Avoid the Cheapest Metal Fabrication Quote

When searching for a company to handle your metal fabrication project, cost is a major factor. You might be tempted to choose the lowest quote you find in order to save money. However, cheaper isn’t always better with these quotes. Unfortunately, you’ll often find that the lowest quote, especially a quote significantly lower than all other quotes, will cost you more in the long run. Here are some of the reasons you shouldn’t always choose the cheapest metal fabrication quote.

Topics: metal fabrication quote, Working With A Metal Fabrication Company

Tips to Find a Connecticut Laser Cutting Services Partner

Finding the right laser cutting partner can be tricky due to a wide variety of factors. Often, laser cutting service partners are selected based solely on their ability to provide a low cost solution. While cost remains a critical factor in any decision, it’s important to consider the company’s overall capabilities, experience, and quality. This blog post aims to help procurement professionals develop useful questions to ask potential partners.

Topics: Laser Cutting Services, Laser Cutting Capabilities, Working With A Metal Fabrication Company

How Does Aluminum Compare to Steel for Fabrication Projects?

Aluminum and steel are pillars of the metal manufacturing industry. Both aluminum and steel are synthetic alloys; in other words, they don’t appear in nature and must be created using other basic elements. Aluminum must go through ha few phases before it appears like the shiny silver metal that you’re familiar with. The base ingredient of aluminum is a mineral called bauxite, which is mined primarily in tropical areas. The bauxite is ground into a thick paste called alumina, which is then smelted with molten cryolite and shocked with electricity. The ions separate, and the residual liquid cools and becomes aluminum.

Topics: Metal Fabrication, Custom Metal Fabrication, steel cutting

What are the Different Options for Metal Finishing?

Finishing is the final step in preparing metal products for use, a crucial component for any metal fabrication project. Finishing helps to make products more resistant to corrosion, while providing higher electrical, chemical or tarnish resistance.

Beyond that, finishing adds additional durability and makes metal surfaces look their best. For most projects, a product’s finish is determined by its intended use. This post will provide a brief overview of the different types of metal finishing, while offering several factors to consider when choosing a finishing method.

Topics: Metal Finishing

An Overview for Beginners: What is Metal Fabrication?

Fabricated metal products are very common, however, few people understand how the metal fabrication process works. In fact, many people think of welding when they hear metal fabrication, despite the fact that welding is only one process that metal fabricators use. This post will examine several different factors of metal fabrication to help educate you before the next situation when you need to rely on the services of a metal fabrication company

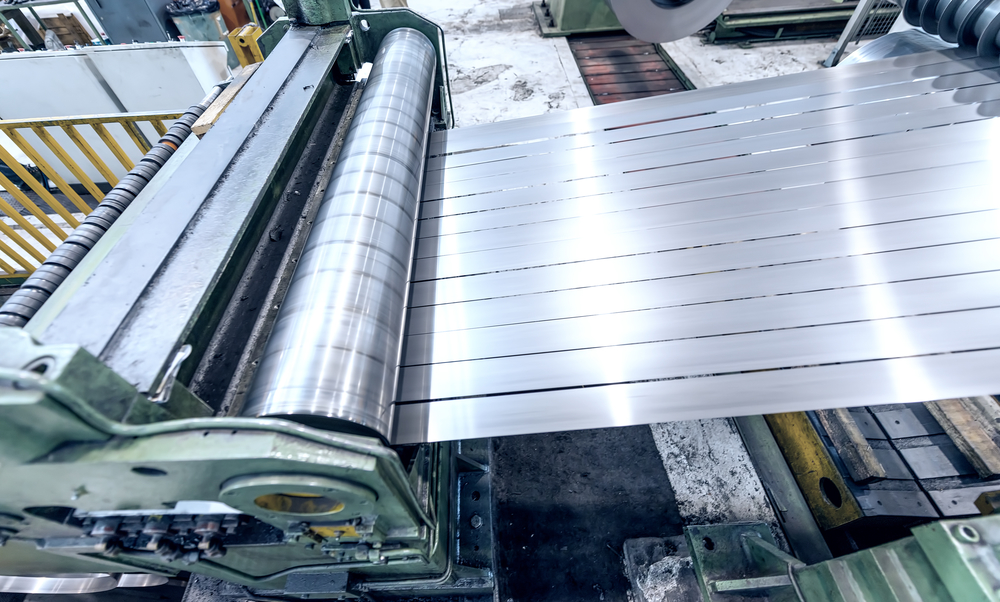

So, what exactly is metal fabrication?

Simply put, Metal fabrication is a manufacturing process used to shape metal into parts or end products. CAMM Metals uses a wide variety of techniques to shape sheet metal into a part or good. Many metal fabricators use sheet metal, which can be up to .25 inches thick. Fabricators then convert this sheet metal into products or tools. We cut, fold, or shape metal to create the finished part.

Although metal fabrication can be used to mass produce products, it can also be used to create large runs of customized fabricated metal products. These projects typically include the design and fabrication of customized metal parts to fit a businesses’ needs. We’ve covered some of our custom projects in the past, like a custom fuel pump test stand and a custom beer tank (insert links).

Topics: Metal Fabrication Process, Working With A Metal Fabrication Company

Adhering to the guidelines associated with design for manufacturing (DFM) ensures that a sheet metal design flows through the processes without issues. This ultimately helps to improve lead times and lowers the overall project cost. Fortunately, there are numerous techniques you can use to increase the chances your sheet metal part is ready for manufacturing.

Topics: Custom Sheet Metal Fabrication

4 Common Misconceptions About Pricing for Metal Fabrication

If you’re searching for a metal fabrication company to help complete your latest project, it’s essential that you understand how to acquire an accurate estimate.

If you’re saddled with a vague understanding of your project, it’s possible that you could get burned on an estimate. Whether you’re seeking to hire a team for a small done-in-a-day welding project or a nuanced and lengthy metal fabrication project, steer clear of these common misconceptions to get the most accurate estimate.

Topics: Metal Manufacturing Myths, Metal Fabrication Projects, Saving Money on Metal Fabrication, Working With A Metal Fabrication Company

What are the Key Advantages of Fiber Laser Cutting Machines?

All laser cutting processes have their own inherent advantages and disadvantages, but it appears that the benefits of fiber laser cutting machines far outweigh that of any of the other processes. It’s one of the newest forms of laser cutting, as it’s only picked up traction in the last couple decades or so. However, the benefits that fiber laser cutting machines provide, which we will discuss below, have been quickly realized by metal fabricators all over the country. Fiber laser cutting machines can easily and seamlessly adapt between industries for a huge range of applications. Continue reading to learn more about the other benefits of these powerful machines.

Topics: Laser Cutting, Laser Cutting Services, Laser Cutting Process, Fiber Laser Cutting