Waterjet cutting machines have the ability to cut through metal, plastics, and even carbon fiber without the risk of warping or distortion. Over the years, as the popularity of waterjet cutting has increased, there have been some myths and misunderstandings surrounding the technique that have left many confused as to what a waterjet machine is actually capable of. To help alleviate some of these misconceptions, we have written this post to help you better understand the process.

Debunking 5 Persistent Myths About Waterjet Cutting

Topics: Metal Fabrication, Waterjet Cutting

Machining time has a large impact on the pricing of CNC machined parts. . Machining time’s impact on cost is often greater than the material costs, set-up costs and even the costs of custom finishes. From this, it’s apparent that the secret to cutting CNC machining project costs is cutting down on machining time whenever possible (without sacrificing quality, of course). The more that engineers can optimize their designs to decrease cutting time, the more economical the parts become. We’re here to help, so we’ve compiled a brief list of CNC machining cost reduction tips that you can use on your next project.

Topics: CNC Machining

Simply put, steel fabrication is the process involving the transformation of raw steel into a product or item that can be used in construction or assembly. Steel is considered an alloy of iron and other metals. There are a wide variety of different kinds of steels, which are used in structural and fabrication operations. Essentially, fabrication is basically making a metal into the shape you need.

This blog post will provide a brief overview of steel fabrication, discussing the basic methods of fabrication as well as the basic raw materials involved.

Topics: Steel Fabrication

A new generation of computer programmers and design engineers have transformed the practice of machining into a precision art, CNC machining (computer numerical control). The manufacturing industry depends heavily on CNC machines, replacing certain operations that once required engineer operated equipment like vertical millers, routers and shaping machines.

Despite the ubiquitous nature of CNC machining in manufacturing, we still receive inquiries questioning the benefits of this process. Continue reading to learn the basic benefits associated with using CNC machining for your next project.

Topics: CNC Machining

4 Factors that Affect the Cost of Metal Fabrication

Proper, detailed planning is crucial for large-scale fabrication projects. Typically, cost estimation is a main component throughout the planning process. Beyond that it’s important to specify the parameters of the project and identify whether it will involve specially crafted elements like structural steel or sheet metal.

The advancements in modern technology and machines have made it easier to complete a project with cost-efficiency in mind. Yet, despite the reduction in metal fabrication costs, it’s still valuable to properly estimate the cost of your project. This post provides a brief overview of the factors that affect the cost of metal fabrication projects.

Topics: Project Cost, Metal Fabrication

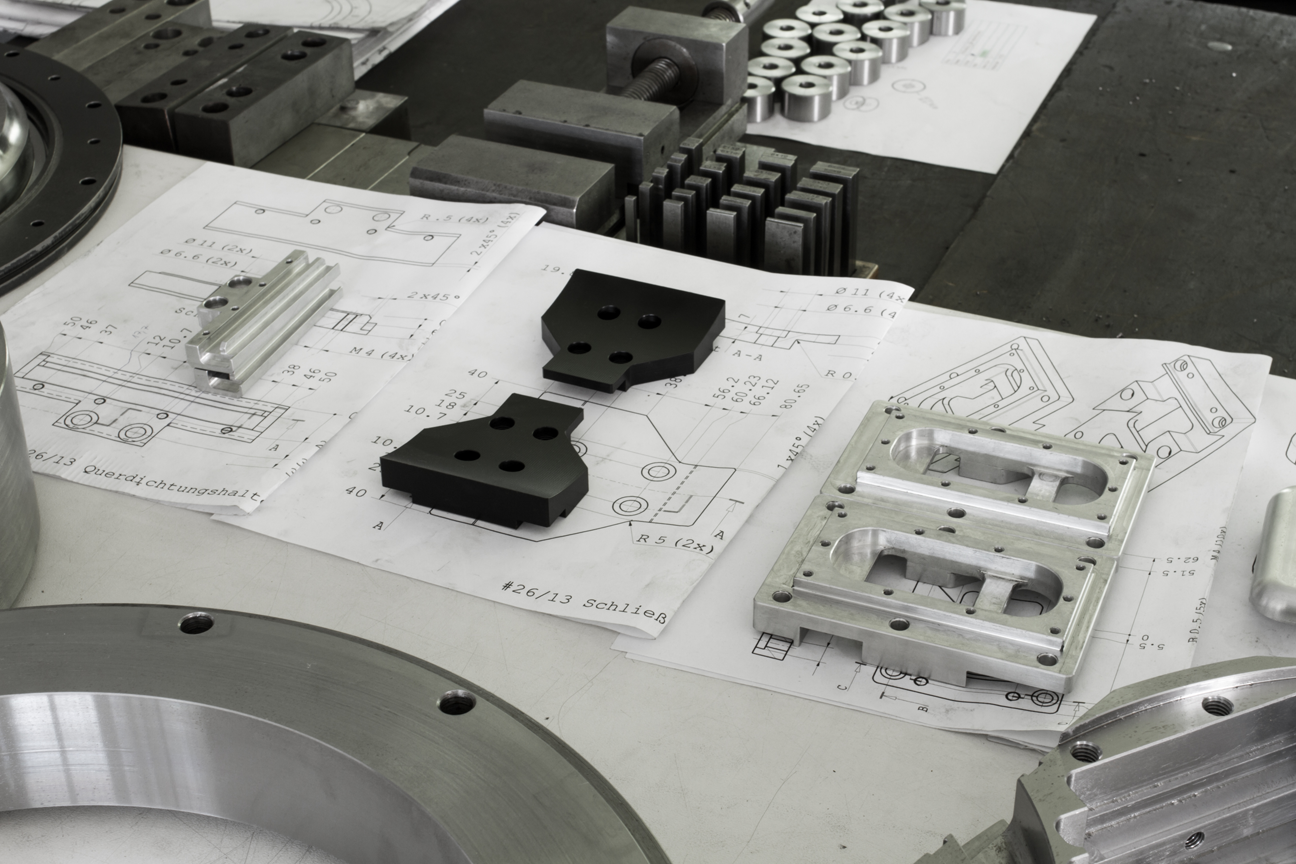

What Engineers Need to Know about Metal Fabrication

Engineers are skilled and knowledgeable about their industry but that doesn’t mean they fully understand how to optimize a product or component design for metal fabrication. Working with a metal fabrication company can help engineers with the metal fabrication technology and design trends. This articles discusses tips for engineers on what they need to know about metal fabrication.

Topics: Metal Fabrication

Custom metal fabricators work with several types of industries on many diverse applications using different types of metals. Strength, conductivity, flexibility and resistance to corrosion are all preferred properties. Through varying fabrication procedures in machining, cutting and welding, these common custom metals can be used in a variety of products. This article highlights the 3 types of metal used for metal fabrication.

What’s The Difference Between Ferrous and Non-Ferrous Metals?

It’s a common question metal fabricators are asked: “So what’s the difference between ferrous and non-ferrous materials?” Knowing the different materials is important to understand what types of metals are best for your project. Read this blog to learn more about ferrous and non-ferrous metals as well as some of the metals that make up those categories.

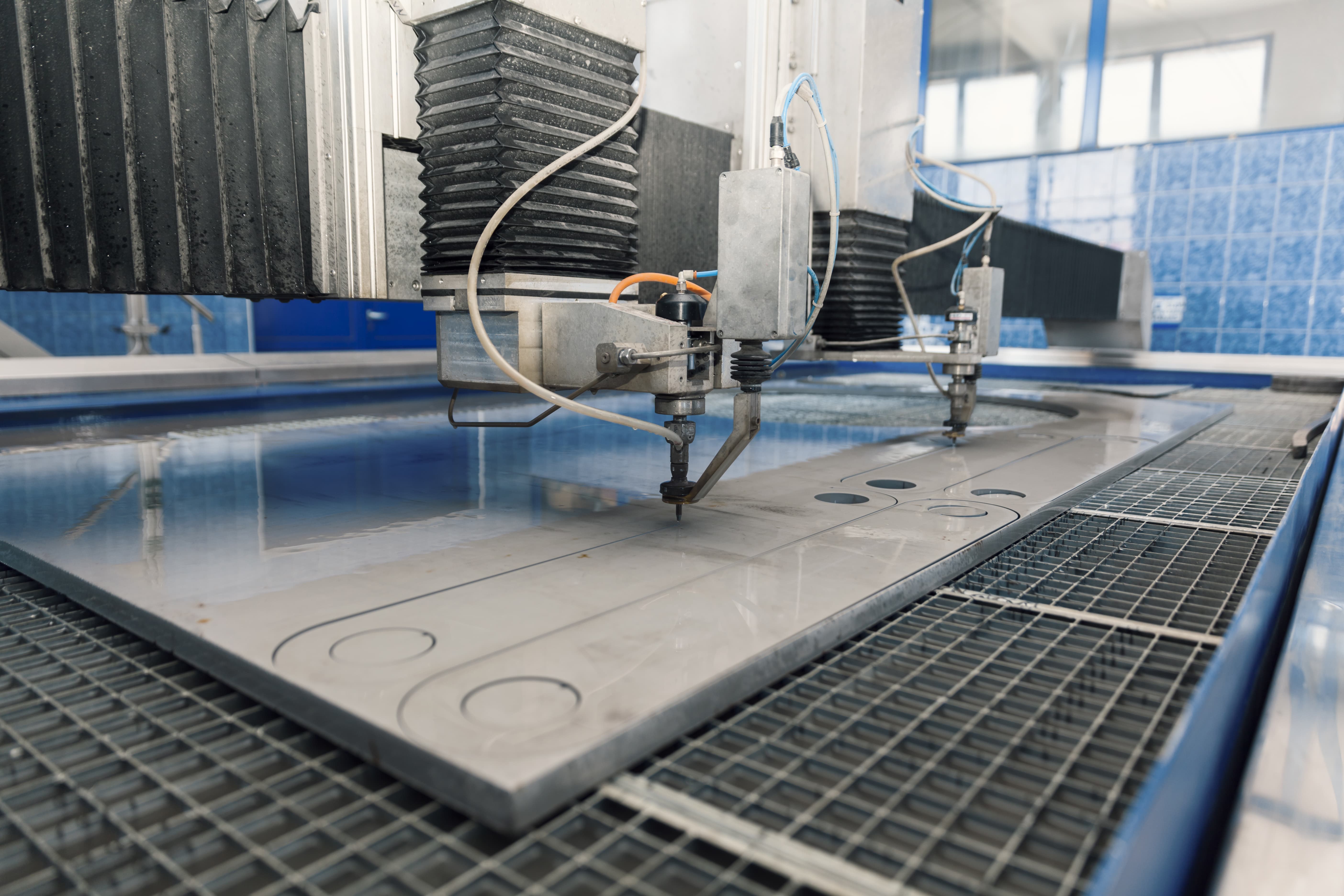

Waterjet cutting offers a unique process that can provide a quality cut edge, while typically eliminating the need for secondary finishing processes.

These machines are fast, flexible, and precise, offering a set of unique benefits when compared with other metal fabrication techniques.

This post provides an overview of some of the basic advantages of waterjet cutting technology.

What to Look for When You're Hiring a Metal Fabrication Company

Every metal fabrication company offers something unique, so how do you choose the one that will ultimately best suit your project needs? Some companies prioritize bulk production runs at a lower cost, while others cater to smaller business with more options for customization. From capabilities to quality to experience, we'll discuss a few factors to consider when choosing a metal fabrication company for your next big project.