The state of manufacturing is constantly changing. New developments in technology in recent years have sped up this processes of change, meaning things are moving faster than ever. In order to stay relevant and have the most efficient manufacturing systems in place, it’s important to stay up to date on the latest trends. Read below for some of the biggest trends in manufacturing this year.

CAMM Metals

Recent Posts

When is it Appropriate to Use Stainless Steel Grain Finish?

Stainless steel has a wide variety of applications and a range of finishes to choose from. Each type of finish is well suited to different types of projects. A grain finish will be coarser with visible grains. It will lack a shiny or mirrored finish, causing it to hold up to wear and tear over time. Here are some of the main applications for stainless steel grain finish!

Industrial Applications With Heavy Traffic

Stainless steel grain finish is a great option for industrial applications with heavy traffic such as elevator wall panels and escalator parts. The material will maintain an attractive appearance through years of wear and tear, making it ideal for heavy use. Additionally, its dull sheen makes scratches and other damage not easily visible. Stainless steel grain finish is a great option for industrial applications that have heavy usage because it will hold up over time and maintain its attractive appearance.

Topics: stainless steel, Grain Finish

Over time, cutting tools can chip and wear, eventually rendering them useless. Every tool has a lifespan and replacing tools is inevitable. However, there are some strategies that will help minimize damage and extend the life of your tools. Here are some tips to help you extend the life of your cutting tools.

Topics: Metal Cutting, Extending Tool Life

Welding is an important part of the metal fabrication process. However, there are many different issues that can arise from welding. Without proper technique, there are many different problems that can occur. Here are some of the most common problems that occur with welding and how to fix them.

Topics: Welding, Welding Problems

Going Green: How Steel Fabrication Facilitates the Green Energy Industry

Renewable energy is becoming increasingly important and increasingly profitable in this day and age. There are many different industries that profit from this increasing importance of the green energy industry. These industries are essential to the growth and success of renewable industry. One industry that allows the green energy industry to flourish is steel fabrication. Without steel fabrication, many of the products that are essential to facilitating renewable energy would not be possible. Read below to learn about the different ways in which steel fabrication facilitates the green energy industry.

Topics: Steel Fabrication, Steel Fabrication and Renewable Energy, Green Energy Industry

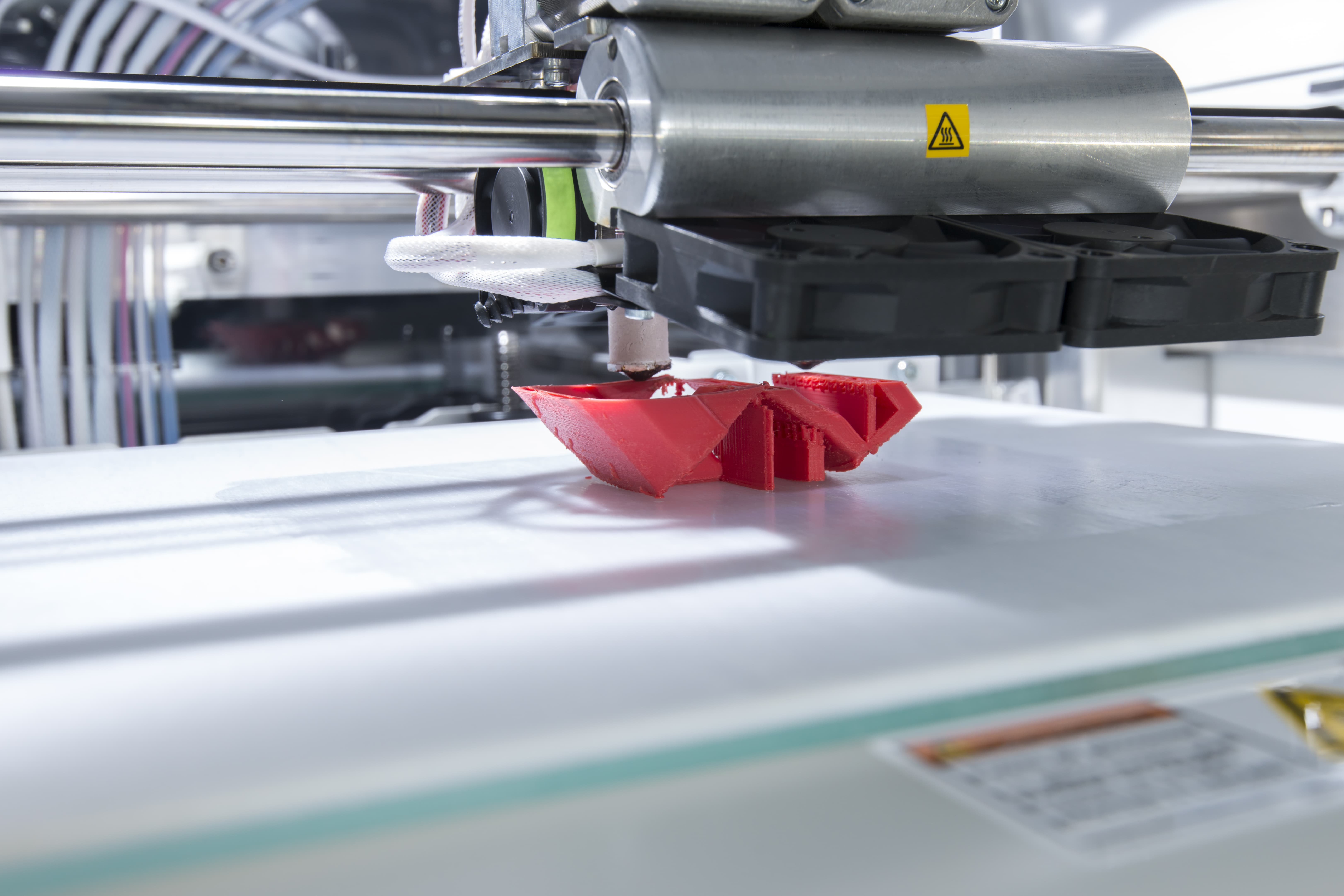

Three-Dimensional printing is a fairly new process with many different applications. Many manufacturers have invested in 3D printers because they understand their value and the wide variety of products 3D printers enable manufacturers to create. If you're curious about 3D printers, here is a breakdown of the 3D printing process and its advantages.

Topics: 3D Printing, 3D Printing Applications

What are the Common Mistakes to Avoid When Designing for Manufacturing?

Designing products for manufacturing requires a mentality that necessitates a constant vigilance to design parts with their future manufacturing requirements in mind. By taking certain aspects into consideration early on, it’s less likely that you will have to return to your design for drastic changes later on, likely saving you both time and money.

CAMM Metals CAD program offers real-time feedback for machined parts, but there are some design choices you can make to avoid encountering future issues. Here are some common mistakes we’ve noticed in designs for manufacturing that are easily avoidable. Avoiding these mistakes will help to save time and money over the lifecycle of a product.

What are the Top Mistakes to Avoid When Handling Stainless Steel?

Stainless steel is a very attractive metal used for various types of projects. However, because its surface is so polished, scratches and other damage are more likely to show up than in other metals. Because stainless steel is so susceptible to damage, it’s easy to make a mistake when handling the material. Here are some of the common mistakes that people make when handling stainless steel.

Topics: stainless steel fabrication, stainless steel, Stainless Steel Maintenance

CNC machining has become one of the most important and efficient means of handling metal fabrication tasks in modern American industry. This is because the technology itself is a combination of sophisticated software programming married to advanced mechanical engineering to produce a system known as “computer numerical control,” or CNC. The manufacturing industry depends heavily on CNC machines, replacing certain operations that once required engineer operated equipment like vertical millers, routers and shaping machines. So, what’s the reason for the ubiquitous nature of CNC machining in the manufacturing industry? This blog post will briefly explore several benefits associated with CNC machines.

Topics: CNC Machining

Why is Deburring Important for Metal Fabrication Projects?

Regardless of the industry you’re in, accuracy matters— it’s critical to have dependable machines and parts that produce accurate, repeatable, and predictable results time and time again.

Topics: Custom Metal Fabrication, Deburring

-min.jpeg)