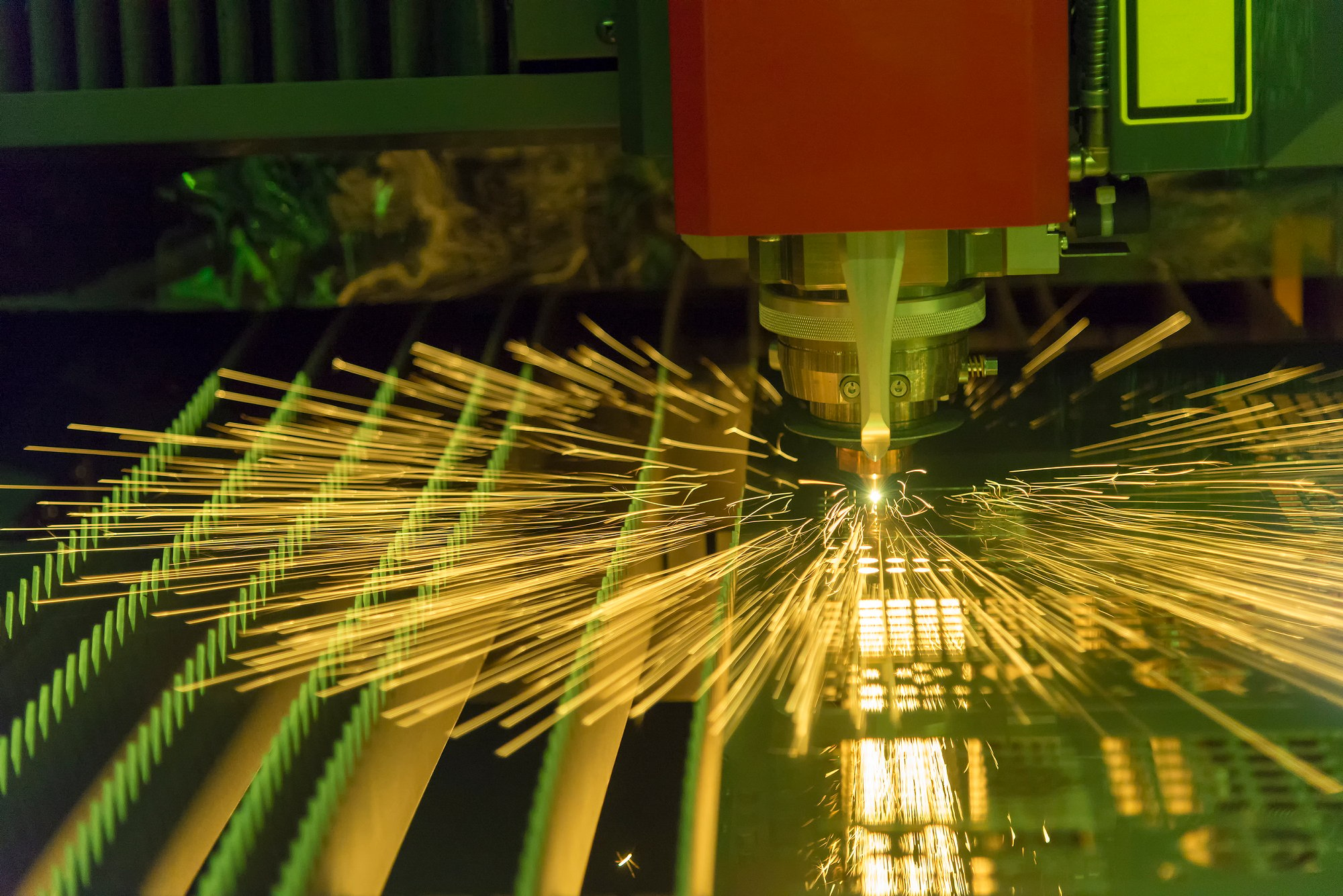

Laser cutting is an advanced technology used in many metal fabrication projects. There are many different methods that fabricator use for cutting metal, but laser cutting is one of the most advanced techniques. Fabricators often choose laser cutters because of their ability to make precise cuts at speeds unmatched by other flat sheet cutting methods. Continue reading to learn about the benefits of using laser cutters for sheet metal fabrication projects.

Competitive Pricing

The costs associated with laser cutting, like many other processes, is determined by labor, operation and machine costs. Since laser cutting is a highly automated process, labor costs are minimal when compared to hand-operated machinery. Operating costs and machine costs are average compared to other cutting techniques.

Typically, outsourcing laser cutting is the most effective option for most projects, as laser cutting machines can be quite expensive. If you opt to work for a manufacturer who already has laser cutting capabilities, this is cost can be greatly mitigated. Beyond that, since a laser doesn’t get dull or worn, you won’t have to worry about die changeover mid-process. So, the larger the order you place, the most cost-efficient laser cutting becomes, since you can flip a switch and let it run. The larger your order, the more cost-effective the entire process will be.

Overall, laser cutting isn’t the cheapest cutting technology available, but it’s more than affordable for most projects, especially compared with water jet cutting or hand cutting processes.

Unrivaled Speed, Efficiency & Automation

A laser cutting machine can move as quickly as ___” per minute. Of course, the exact speed will vary depending on tolerances and intricacy of the parts.

Laser cutting is run by CNC controls. The formulas entered into the computer means each part and product is identically fabricated, leading to fewer defects per batch.

Quality Precision

Laser cutting can create incredibly small cuts at tight tolerances (.___” on average). However, that’s the tradeoff: the more precision you want, the slower the laser will move. Yet, this highly detailed capability is unique to laser cutting. So, if you require intricate cuts, laser cutting is the only type of cutting that will get the job done well.

Beyond that, all laser cut edges and curves are smooth, sharp, and clean, which means there is very little, if any, burring because the laser melts rather than physically cuts the metal.

The only thing to consider is if your project requires very thick sheets of metal - thicker metals affect the quality of the cut, and a laser will leave some dross (melted metal scum) behind on thick metals. Aside from this dross, there is little to no clean up involved in the majority of laser cutting projects.

Versatility

The combination of cost, speed, automation, and precision make laser cutting a great choice for any size product or project. This makes a lot of routine tasks/projects easy, including prototypes, industrial orders, delicate designs, and larger cutouts. Lasers are capable of making holes, slots, tabs, and other cut fabrications with no interruption of the cutting process. The incredible precision allows for tight tolerances on intricately detailed designs. If your project doesn’t require tight tolerances, the laser can move quickly and produce parts at incredible speeds. This makes laser cutting a fantastic choice for a wide spectrum of projects.

CAMM Metals | Laser Cutting Services in Connecticut

CAMM Metals is proud to offer laser cutting services for your next fabrication product. We can fabricate any order, whether it includes prototypes, components, or final assemblies. We adhere to the belief that high quality results can only be achieved through the use of high quality equipment. Our technicians operate the Prima Power PLATINO® Fiber 2D laser cutting machine, offering the fastest cutting speeds on the market! Laser cutting offers the ability to cut through a wide variety of materials and thicknesses at high speeds, producing extremely precise and accurate cuts.